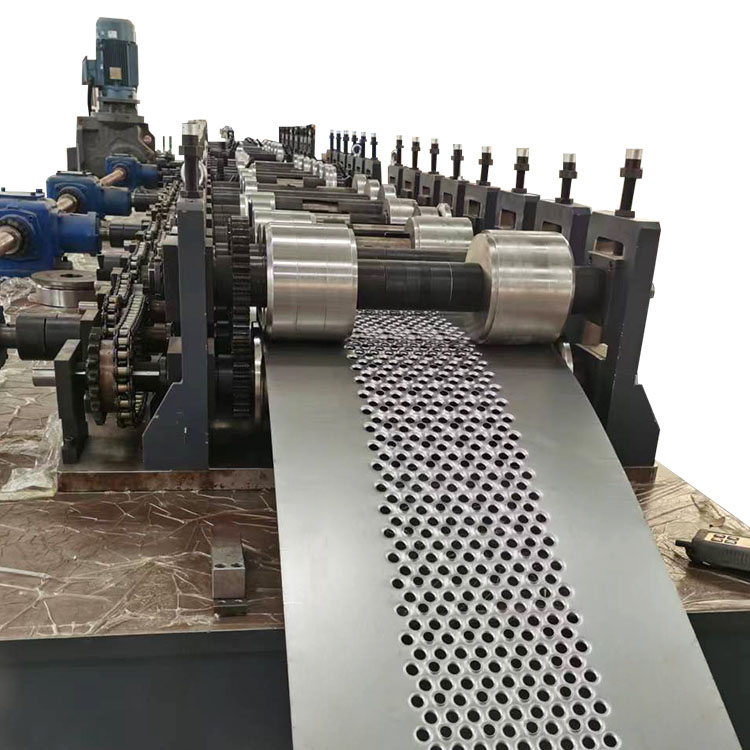

Roll Forming Machine for Strut Channel Support System

Strut Channel Support System Roll Forming Machine: Revolutionizing the Construction IndustryThe construction industry is constantly evolving, seeking new methods and technologies to improve efficiency and reduce cost. In line with this ongoing pursuit, a leading manufacturing company has announced the launch of their latest innovation – the Strut Channel Support System Roll Forming Machine. This cutting-edge machine promises to revolutionize the construction process, providing builders with a faster, more efficient, and cost-effective solution.Traditionally, builders have relied on manual processes to fabricate support systems for various structures. This tedious and time-consuming task not only slows down the construction process but also adds to the overall cost. Moreover, manual fabrication often encounters inconsistencies and imperfections, resulting in compromised structural integrity. Recognizing these challenges, the manufacturing company has developed the Strut Channel Support System Roll Forming Machine.Designed with state-of-the-art technology and precision engineering, this machine automates the roll-forming process, eliminating the need for manual labor. By efficiently converting raw materials into strut channels, the machine ensures consistent and high-quality results, free from human errors. This guarantees the structural integrity of the support systems, reduces the risk of failures, and enhances overall safety on construction sites.With its high-speed operation, the Strut Channel Support System Roll Forming Machine significantly increases the productivity of construction projects. Builders can now fabricate support systems at an unprecedented pace, allowing them to meet strict deadlines and complete projects on time. This machine is capable of producing large quantities of strut channels in a short span of time, making it ideal for both small and large-scale construction projects.Apart from saving time, the machine also offers substantial cost savings. By eliminating manual labor and the associated costs, builders can reduce their overall project expenses. Additionally, the machine enhances material utilization by minimizing waste, meaning builders can optimize their available resources, leading to further cost reduction. This cost-effectiveness makes the Strut Channel Support System Roll Forming Machine a valuable asset for construction companies seeking to maximize efficiency and profitability.Furthermore, the machine's flexibility and versatility make it suitable for a wide range of construction applications. Whether it's for commercial buildings, industrial facilities, or residential projects, the Strut Channel Support System Roll Forming Machine can adapt to various design requirements and specifications. This adaptability saves builders from investing in multiple machines, hence reducing capital expenditure and improving operational efficiency.In addition to its immediate benefits, the Strut Channel Support System Roll Forming Machine aligns with the broader goals of sustainable construction practices. The machine efficiently utilizes raw materials, reducing waste and minimizing the environmental footprint associated with construction projects. By adopting this innovation, builders can demonstrate their commitment to sustainable practices while reaping the practical advantages it offers.The manufacturing company behind this pioneering technology has a long-standing reputation in the industry. With a mission to provide innovative solutions to the construction sector, they have consistently delivered cutting-edge products and equipment. Over the years, their commitment to quality, efficiency, and customer satisfaction has earned them a loyal customer base, comprising top construction firms worldwide.The introduction of the Strut Channel Support System Roll Forming Machine establishes this company as a trailblazer in the field of construction technology. Their continuous investment in research and development enables them to stay ahead of the competition and cater to the evolving needs of the industry.As the construction industry continues to evolve, innovation plays a vital role in driving progress. The Strut Channel Support System Roll Forming Machine represents a breakthrough in construction technology, bringing reliable, efficient, and cost-effective solutions to builders worldwide. With this cutting-edge machine, the construction process will be revolutionized, delivering safer, faster, and more sustainable projects.

Read More

Discover the Advantages of Cold Roll Forming Technology for Efficient Metal Fabrication Processes

[Company Name] Introduces Advanced Cold Roll Forming Technology[City, Date] - [Company Name], a leading manufacturer in the cold roll forming industry, is revolutionizing the manufacturing process with its latest advanced technology. Developed in-house by their team of experts, the new cold roll forming technology is set to enhance production capabilities and provide superior quality products.Cold roll forming is a highly efficient and versatile metal forming process used in a wide range of industries. It involves continuously bending a long strip of metal through a series of roll stands to achieve a desired shape and profile. This method offers significant advantages over traditional hot rolling, as it enables precise control of metal thickness, complex shapes, and consistent high-quality results.[Company Name] has been at the forefront of the cold roll forming industry for several years, offering innovative solutions to meet the varying needs of its customers. With the introduction of their latest technology, the company is once again pushing the boundaries of what can be achieved through cold roll forming.One of the key features of this new technology is its advanced control system, which allows for real-time monitoring and adjustment of the roll forming process. By constantly analyzing data and making instant adjustments, [Company Name] ensures precise and accurate shaping of metal profiles, minimizing material waste and maintaining consistent quality throughout production.In addition, the new technology incorporates state-of-the-art sensors and measurement devices to ensure optimal performance. These sensors provide accurate readings of various parameters such as thickness, width, and curvature, allowing for seamless control and improved efficiency. The collected data is also used for further analysis and optimization of the entire manufacturing process.With this advanced cold roll forming technology, [Company Name] is able to offer its customers a wider range of options and possibilities. The flexibility of the process allows for the production of complex and intricate profiles, meeting the most challenging design requirements. Whether it's creating custom shapes for the automotive industry or manufacturing precise components for the construction sector, [Company Name] is well-equipped to cater to diverse market demands."We are thrilled to introduce our latest cold roll forming technology to the industry," said [Company Name]'s CEO. "This innovation represents a significant milestone in our ongoing commitment to providing cutting-edge solutions and exceptional quality to our customers. We believe that this technology will revolutionize the way metal profiles are manufactured, opening up new opportunities and setting new standards in the industry."To ensure seamless integration of the new technology, [Company Name] has also invested in training its workforce. Employees have undergone extensive training programs to fully understand and operate the advanced control system and other features of the technology. This enables the company to maintain high standards of performance, efficiency, and quality across all aspects of its operations.As [Company Name] continues to lead the way in the cold roll forming industry, this new technology further establishes their position as a trusted and innovative manufacturer. With enhanced capabilities and a strong focus on quality, the company is prepared to meet the evolving needs of customers and provide reliable solutions for diverse applications.About [Company Name]:[Company Name] is a renowned manufacturer in the cold roll forming industry, specializing in the production of high-quality metal profiles for various sectors. With a commitment to innovation and superior customer service, the company has earned a reputation for delivering reliable solutions that meet the highest standards.

Read More

Efficient and Reliable Steel Stud Forming Machine: Unlocking Construction Possibilities

Title: Revolutionary Steel Stud Forming Machine Puts Industry Giant at the Forefront of Innovation Introduction:{Company name} has once again pushed the boundaries of industrial innovation with the introduction of their state-of-the-art Steel Stud Forming Machine. This groundbreaking device not only improves production efficiency but also sets new industry standards for quality and precision. By incorporating cutting-edge technology, {Company name} solidifies its position as a front-runner in the construction equipment market, offering unprecedented opportunities for growth and success.Section 1: Industry ChallengesThe construction industry has long faced challenges in terms of cost, time, and quality. Traditional methods of manufacturing steel studs required manual labor, leading to inconsistencies in dimensions and a higher risk of errors. This predicament not only added to construction time but also increased the overall costs associated with the production process. Section 2: The Steel Stud Forming Machine {Company name}'s innovative Steel Stud Forming Machine is specifically designed to address these challenges. This new technology streamlines the production process, significantly reducing human error and labor costs. By automating the manufacturing process, the machine is not only capable of producing steel studs of superior quality but also ensures uniformity in dimensions, promoting a smoother construction process.Section 3: Unrivaled Precision and EfficiencyThe Steel Stud Forming Machine sets itself apart from competitors by offering unparalleled precision. Equipped with advanced sensors, the machine boasts an impressive accuracy rate, minimizing waste and optimizing material usage. The integrated software provides real-time feedback, granting operators greater control over the manufacturing process, and allowing for quick adjustments and corrections.Moreover, the machine's high-speed production capability elevates efficiency to new heights. It can churn out steel studs at an impressive rate, reducing lead times and meeting project deadlines more effectively. With this level of efficiency, {Company name} ensures that their customers have the competitive advantage required to succeed in today's fast-paced construction industry.Section 4: Enhanced Durability and Increasing Environmental ConcernsIn addition to its numerous functional advantages, the Steel Stud Forming Machine also contributes to environmental sustainability. By utilizing eco-friendly materials and reducing waste, the machine aligns with global efforts to minimize carbon footprints and promote greener construction practices. This aspect appeals to large-scale builders seeking to adopt environmentally conscious solutions without compromising quality or productivity.One of the most significant advantages of steel studs lies in their durability. The inherent strength of steel significantly prolongs the lifespan of structures. Enhanced durability translates into reduced maintenance costs, long-term sustainability, and increased customer satisfaction. With the introduction of the Steel Stud Forming Machine, {Company name} enables construction companies to harness these benefits efficiently.Section 5: Expanding Market Reach and Global ImpactWith its groundbreaking Steel Stud Forming Machine, {Company name} not only secures its position as an industry leader but also creates tremendous growth opportunities. The worldwide demand for efficient construction solutions continues to rise, presenting immense potential for international expansion. By offering cost-effective, high-quality steel studs, {Company name} establishes itself as a global player in the construction equipment market, contributing to economic growth worldwide.Conclusion:The introduction of {Company name}'s Steel Stud Forming Machine marks a pivotal moment in the construction industry. By combining cutting-edge technology, unparalleled precision, and unrivaled efficiency, {Company name} has elevated steel stud manufacturing to new heights. With a focus on durability, environmental sustainability, and enhanced construction practices, the company cements its commitment to delivering innovative solutions with a global impact. As the industry giant paves the way for future advancements, customers can expect more groundbreaking technologies that revolutionize the construction landscape.

Read More

Efficient and Advanced Roll Forming Machine: Streamlining Production Processes

Roll Forming Machine: A New Revolution in the Metal Forming IndustryThe metal forming industry has been thriving for centuries, and it has witnessed several improvements over the years. With the emergence of technology in the industry, companies have been able to enhance productivity and efficiency, leading to better quality products. One innovation that has changed the face of metal forming is the use of Roll Forming Machines.Roll Forming Machines are a type of equipment used in the metal forming industry to shape metals into various designs and forms. They are made up of rollers, which guide the metal sheet through a series of bend points to create the desired shape. Roll forming machines are widely used in the automotive, construction, furniture, and packaging industries, among others.A great Roll Forming Machine company is (need to remove the brand name), a manufacturer that has been in operation for over 20 years. They specialize in manufacturing high-quality Roll Forming Machines that are efficient and durable. The company has a team of experts dedicated to developing and testing the machines to ensure they meet the industry standards.Their machines are designed to handle various materials, including aluminum, copper, and stainless steel. The high precision rollers ensure that the final product is of high quality and meets the design specifications. The Roll Forming Machines are also designed with safety features to ensure that the operators are protected from any accidents that may occur during the metal forming process.Roll Forming Machines have several advantages over traditional metal forming methods. Firstly, the machines are designed to be very effective, producing more products in a shorter time than traditional metal forming methods. Secondly, they are much more precise, ensuring that each product is made to exact specifications. Furthermore, the machines can be programmed to produce different shapes, making them versatile and suitable for various industries.Roll Forming Machines are also much more efficient than traditional metal forming methods. This is because they require fewer manual processes, leading to less wastage, and lower production costs. The machines can also be automated, which reduces the need for operators and enhances productivity.Another advantage of Roll Forming Machines is that they can handle a wide range of materials. This makes them suitable for producing different types of products used in different industries. Since the machines can shape metal sheets into various designs, they can be used to produce products such as lockers, doors, frames, and panels.Roll Forming Machines have transformed the metal forming industry, making the process faster, more accurate, and efficient. The use of these machines has led to the production of high-quality products, which has increased customer satisfaction and loyalty. Companies that use Roll Forming Machines have also been able to increase their revenue, as they are now able to produce more products at a faster rate and lower production costs.Metal forming companies looking to improve their production processes should switch to Roll Forming Machines. However, it is essential to choose a reputable manufacturer such as (need to remove the brand name), to ensure that the machines are of high quality and meet industry standards.In conclusion, Roll Forming Machines are revolutionizing the metal forming industry, leading to increased efficiency, productivity, and higher quality products. Metal forming companies should consider implementing these machines to stay ahead of the competition and improve their position in the industry.

Read More

Revolutionary New Technology: Multi Profile Stud Machine Changes the Game" - Rewritten SEO Title: "Innovative Multi Profile Stud Machine Transforms Construction Industry

Multi-Profile Stud Machine Offers Versatile Solutions for Construction IndustryIn recent years, the construction industry has witnessed a rapid growth with the increasing demand for buildings and infrastructure worldwide. As a result, there is a corresponding need for innovative technologies that can simplify the construction process while maintaining quality. One such technology is the Multi-Profile Stud Machine, which offers versatile solutions for construction industries.Different buildings come with varied designs and requirements, which necessitates the use of construction materials that can meet these diverse needs. Among these materials are metal studs, popularly used in the building industry as they offer cost-effectiveness, durability, and ease of installation. However, finding a metal stud machine that can manufacture various sections without compromising on precision can be a challenge.Enter the Multi-Profile Stud Machine, which is fast gaining popularity in the construction industry. This equipment is specially designed to manufacture metal studs of different profiles, widths, and thicknesses. It offers a one-stop solution for construction firms that require metal studs to meet unique building specifications.The Multi-Profile Stud Machine is manufactured by a leading company with vast experience in the industry. The company has a reputation for producing high-quality metal forming machinery. They have invested in cutting-edge technology to develop the Multi-Profile Stud Machine, which delivers exceptional performance, versatility, and reliability.With its advanced capabilities, the Multi-Profile Stud Machine allows construction firms to create studs with intricate shapes and diverse sizes within seconds. This eliminates the need to make several tool changes, saving time and increasing productivity. It also ensures precision and consistency in every stud manufactured, maintaining high-quality standards.The Multi-Profile Stud Machine provides an additional layer of flexibility to construction firms, enabling them to meet the unique requirements of each project. The machine makes it possible to manufacture studs in a range of profiles, such as C-channels, U-channels, furring channels, and wall angles. It can also make different sizes and thicknesses, allowing construction firms to customize their studs to exact specifications.One essential feature of the Multi-Profile Stud Machine is its ease of use. The equipment comes with straightforward controls that are easy to understand and operate. This enables operators to set up and create metal studs quickly, reducing downtime. The machine is also highly ergonomic, making it easy to load and unload materials. This reduces the likelihood of operator fatigue and improves workplace safety.The Multi-Profile Stud Machine also offers significant cost savings to construction firms. Being able to make studs of diverse profiles and sizes eliminates the need to purchase different machines for each profile. This reduces the overall cost of the equipment, lowers maintenance fees, and saves on storage space. Additionally, the machine is highly efficient, producing a larger volume of studs in less time compared to traditional methods.In conclusion, the Multi-Profile Stud Machine is a game-changer in the construction industry, offering versatile solutions to meet essential project needs. Its advanced capabilities make it possible to manufacture studs of different profiles, widths, and thicknesses within seconds. By doing so, it reduces the cost of equipment, maintenance fees, and storage space and increases productivity, maintaining high-quality standards.Construction firms looking to streamline their metal forming processes should consider investing in the Multi-Profile Stud Machine. As a reliable, durable, and efficient equipment, the machine provides an edge over competitors, ensuring high-quality studs for building construction.

Read More

Ultimate Guide to Choosing an Automatic Roll Forming Machine

[Company Name] Launches Innovative Automatic Roll Forming Machine[City, Date] - [Company Name], a leading manufacturer of industrial machinery, has recently unveiled its latest offering - an innovative Automatic Roll Forming Machine. With its state-of-the-art technology and advanced features, this machine is set to revolutionize the roll forming industry.Roll forming is a widely used manufacturing process that involves shaping continuous metal sheets into desired profiles with the help of specialized machinery. Traditionally, this process has been time-consuming and labor-intensive. However, [Company Name] has recognized the need for more efficient and automated solutions, leading to the development of their latest Automatic Roll Forming Machine.Equipped with cutting-edge technology and precision engineering, the Automatic Roll Forming Machine offers a range of benefits that will greatly enhance the efficiency and productivity of industrial operations. The machine utilizes a computerized control system, which allows for easy customization and programming of various profile designs. This significantly reduces downtime between profile changes and ensures seamless production.One of the most impressive features of [Company Name]'s Automatic Roll Forming Machine is its quick roll change system. Typically, changing rolls in traditional roll forming machines can be a time-consuming process. However, with the new machine, roll changes can be completed in a matter of minutes, greatly minimizing production downtime. This not only increases productivity but also provides companies with the flexibility to respond quickly to changing market demands.Furthermore, the Automatic Roll Forming Machine boasts a high-speed production capacity, enabling manufacturers to meet high-volume orders efficiently. Its advanced servo motor drive system ensures precise and consistent material feeding, resulting in consistent product quality. This has a direct impact on customer satisfaction and can significantly reduce rework or scrap materials.In terms of safety features, the Automatic Roll Forming Machine is designed with multiple sensors and safety interlocks to prevent accidents and ensure operator well-being. The machine adheres to strict international safety guidelines and is equipped with emergency stop buttons, guards, and safety light curtains. These safety measures ensure a secure working environment for operators, minimizing risks associated with roll forming operations.[Company Name]'s commitment to quality is evident in every aspect of the Automatic Roll Forming Machine. Each machine undergoes rigorous testing and quality control procedures to ensure reliable performance and longevity. Moreover, the company provides comprehensive technical support, including training and maintenance, to ensure that customers get the most out of their investment.The Automatic Roll Forming Machine has already created a buzz in the industry, with several manufacturing companies expressing their interest in the product. [Company Name]'s commitment to innovation and customer satisfaction makes them a trusted partner for businesses seeking advanced roll forming machinery.With the launch of their Automatic Roll Forming Machine, [Company Name] continues to strengthen its position as a pioneer in the industrial machinery sector. The machine's ability to streamline roll forming operations, improve productivity, and enhance product quality is set to revolutionize the way companies approach roll forming. For more information about [Company Name]'s Automatic Roll Forming Machine, please visit their website or contact their sales team directly.About [Company Name]:[Company Name] is a leading manufacturer of industrial machinery with a global presence. With a rich history spanning several decades, the company has a proven track record of delivering innovative solutions to various industries. Their commitment to quality, reliability, and customer satisfaction has earned them a reputation as a trusted supplier in the market.

Read More

Efficient Roll Forming Machines for Cold Steel: A Game-changer in Metal Fabrication

Title: Advanced Roll Forming Machine Technology Revolutionizes Cold Steel ProductionIntroduction:In an era where technological advancements continuously impact various industries, roll forming machines have emerged as a game-changer in the field of steel manufacturing. The introduction of state-of-the-art roll forming machines has revolutionized the production of cold steel, enabling manufacturers to achieve superior efficiency, precision, and productivity. This article will explore the advancements in roll forming machine technology and how they are transforming the cold steel industry.1. The Role of Roll Forming Machines:Roll forming machines play a vital role in shaping cold steel into various products, including tubes, profiles, and sections. These machines utilize a continuous bending process, transforming flat metal sheets into complex and functional shapes. By gradually bending the metal through a series of rollers, roll forming machines offer enhanced precision, uniformity, and consistency in the cold steel production process.2. Enhanced Efficiency and Productivity:The latest roll forming machines integrate cutting-edge automation features, significantly improving efficiency and productivity. Automated material handling systems ensure seamless material feed, reducing downtime and eliminating errors. Additionally, advanced control systems enable real-time monitoring and optimization, minimizing setup times and increasing overall production rates. These advancements ultimately facilitate a high-volume output of cold steel products.3. Enhanced Precision and Quality:Precision is a critical factor in cold steel production, especially in industries such as automotive and construction. The advanced technology incorporated within modern roll forming machines ensures precise and consistent shaping, resulting in high-quality final products. Computer Numerical Control (CNC) systems allow for accurate positioning of each roller, eliminating errors and reducing material wastage. The rigorous quality control measures implemented in these machines ensure that every cold steel product meets the industry's stringent specifications.4. Versatility and Customization:Roll forming machines have considerably expanded the range of applications for cold steel products. With customizable roller arrangements and adjustable roll gaps, manufacturers are now capable of producing steel products in various shapes, sizes, and profiles. This versatility allows for widespread application of cold steel in the manufacturing of building components, furniture, transportation systems, and other industries. The ability to cater to specific customer requirements has propelled the market demand for cold steel products.5. Advancements in Material Handling:The integration of advanced material handling systems in roll forming machines has significantly enhanced operational efficiency. Automated coil loading and unloading systems expedite the feed process, while automated stacking systems ensure organized and efficient product output. These advancements reduce the need for manual labor, increasing operator safety and reducing production costs.6. Sustainability and Resource Efficiency:Modern roll forming machines embrace sustainability by optimizing material usage and reducing waste. The precision and accuracy achieved through advanced roll forming technology result in minimal material wastage, maximizing resource efficiency. Furthermore, energy-efficient motors and intelligent power management systems minimize energy consumption, contributing to a greener manufacturing process.Conclusion:The advent of advanced roll forming machines has brought significant advancements to the cold steel industry. Improved efficiency, precision, and versatility have revolutionized the production of cold steel, allowing manufacturers to meet increasing market demands. These advancements not only enhance productivity but also contribute to a more sustainable manufacturing process. As manufacturers continue to invest in cutting-edge roll forming technology, the future of cold steel production looks even more promising.

Read More

Latest Steel Profile Forming Technology Revolutionizes Manufacturing Industry

Steel Profile Forming Machine Enhances Efficiency in Manufacturing IndustryIn recent years, the manufacturing industry has undergone a significant transformation due to technological advancements and automation. One such innovation that is revolutionizing the steel manufacturing process is the Steel Profile Forming Machine. This state-of-the-art machinery combines advanced technology and precision engineering to streamline the production of steel profiles, leading to increased efficiency and productivity in the industry.Steel profiles are essential components in various construction projects, including commercial buildings, bridges, and infrastructural developments. Traditionally, the manufacturing process of steel profiles was time-consuming and labor-intensive. However, with the advent of the Steel Profile Forming Machine, these challenges are being addressed and overcome.The Steel Profile Forming Machine is a sophisticated piece of equipment that automates the bending and shaping of steel profiles. This versatile machinery can handle a wide range of steel profiles, including I-beams, angles, channels, and hollow sections. By utilizing advanced computer numerical control (CNC) technology, the machine can precisely manipulate the steel profiles according to the desired specifications.One of the key features of the Steel Profile Forming Machine is its efficiency in material usage. The machine optimizes the cutting and shaping process, minimizing waste and maximizing the utilization of raw materials. This not only reduces material costs but also contributes to a more sustainable manufacturing process, addressing concerns about environmental impact.The automation provided by the Steel Profile Forming Machine also significantly reduces labor requirements. Previously, workers would manually bend and shape steel profiles, a time-consuming and physically demanding task. With the introduction of this machine, the process is now automated, allowing workers to focus on other critical aspects of the production process. This not only enhances productivity but also improves the safety and well-being of workers.In addition to its efficiency, the Steel Profile Forming Machine also offers high precision and accuracy. With the help of CNC technology, the machine can consistently produce steel profiles with exact dimensions, ensuring uniformity and quality in the final product. This level of precision is vital in construction projects where structural integrity is paramount.Furthermore, the Steel Profile Forming Machine is compatible with various software applications, allowing seamless integration into existing manufacturing processes. This compatibility enables manufacturers to easily incorporate the machine into their production line without disrupting current operations. It also provides opportunities for customization and flexibility in the manufacturing process, catering to specific project requirements.As the global demand for steel profiles continues to rise, the Steel Profile Forming Machine is poised to play a crucial role in meeting this demand efficiently. With its advanced technology, efficiency, precision, and compatibility, this machine has the potential to transform the manufacturing industry and drive further innovation in the steel production sector.Company IntroductionWith a long-standing history in the manufacturing industry, {Company name} has established itself as a leader in providing innovative solutions and machinery for various sectors. Committed to technological advancements, {Company name} strives to improve efficiency and productivity in manufacturing processes.One of the company's notable achievements is the development of the Steel Profile Forming Machine. Leveraging its expertise in precision engineering and automation, {Company name} has successfully introduced this advanced machinery to the market, revolutionizing the steel manufacturing industry.{Company name}'s Steel Profile Forming Machine has been widely adopted by steel manufacturers worldwide, receiving positive feedback and recognition for its outstanding performance and reliability. The company's commitment to research and development ensures that the machine stays at the forefront of industry trends and technological advancements.In addition to its machinery offerings, {Company name} provides comprehensive after-sales services and support to its customers. A team of highly skilled technicians and engineers is available to assist with installation, training, and maintenance, ensuring smooth operation and longevity of the machines.With a strong focus on customer satisfaction, {Company name} continuously strives for excellence in its products and services. Through collaborations and partnerships with industry leaders, the company aims to drive innovation and contribute to the growth and success of its customers.In conclusion, the Steel Profile Forming Machine developed by {Company name} is revolutionizing the steel manufacturing industry by enhancing efficiency, precision, and sustainability. This advanced machinery not only streamlines the production process but also improves worker safety and reduces material waste. With its compatibility and flexibility, the machine is poised to shape the future of steel manufacturing and contribute to advancements in the construction industry.

Read More

Revolutionizing Steel Forming: Discover the Future of Automatic Machinery

Innovative Automatic Steel Forming Machine Revolutionizes Construction IndustryAs technological advancements continue to reshape various industries, the construction sector is no exception. One of the latest breakthroughs in the field is the introduction of an unprecedented Automatic Steel Forming Machine by an industry-leading company. This cutting-edge piece of machinery promises to revolutionize steel fabrication, offering precise and efficient manufacturing processes for construction projects of all sizes.The Automatic Steel Forming Machine, developed by a renowned manufacturer committed to providing state-of-the-art equipment, is poised to transform the way steel structures are produced. With its advanced features and capabilities, this innovative machine streamlines the steel fabrication process, dramatically increasing productivity while reducing costs and time constraints.One of the key strengths of the Automatic Steel Forming Machine lies in its intelligent automation technology. Equipped with cutting-edge algorithms and a user-friendly interface, it enables operators to efficiently control and monitor each step of the steel forming process. This ensures precision and accuracy in creating intricate steel components, eliminating human errors and minimizing material wastage.The machine's automated capabilities also significantly reduce the reliance on manual labor, diminishing the associated safety risks and improving overall construction site safety. As worker fatigue is minimized, the Automatic Steel Forming Machine reinforces the promise of increased productivity without compromising the well-being of the labor force.Furthermore, the speed and precision of the Automatic Steel Forming Machine ensure timely project completion, helping construction companies meet tight deadlines and stay ahead of schedule. By streamlining the manufacturing process, the machine optimizes resource allocation while maintaining the highest standards of quality. This not only boosts overall productivity but also enhances client satisfaction and increases competitiveness in the construction market.The ingenuity of the Automatic Steel Forming Machine is not limited to its automation capabilities. A key advantage of this innovative machinery is its versatility, allowing it to produce an extensive range of steel components. From beams and columns to trusses and brackets, the machine adapts to various design specifications, catering to the unique needs of different construction projects.The incorporation of advanced forming techniques has also contributed to the machine's ability to produce structurally sound steel components. With precise bending and shaping mechanisms, it ensures the quality and integrity of each fabrication. The result is a consistent and reliable output, meeting both industry regulations and client expectations.In terms of environmental impact, the Automatic Steel Forming Machine paves the way for eco-conscious construction practices. By minimizing material wastage and optimizing resource allocation, it effectively reduces the ecological footprint of steel fabrication. This commitment to sustainability aligns with the industry's growing emphasis on environmentally friendly construction methods, making the machine a valuable asset for companies striving to achieve greener practices.Recognizing the potential benefits of the Automatic Steel Forming Machine, several construction companies have already embraced this groundbreaking technology. Early adopters have reported remarkable improvements in project efficiency, cost-effectiveness, and overall construction quality. With its vast potential and remarkable track record, the machine is poised to become the go-to steel forming solution for leading construction firms worldwide.As the construction industry continues to evolve, it is imperative for companies to stay ahead of the curve. The introduction of the Automatic Steel Forming Machine marks a major milestone in the quest for innovation and progress, displacing traditional fabrication methods with a highly efficient and automated solution. With its unmatched precision, versatility, and environmental sustainability, this revolutionary machine has transformed steel fabrication, setting new industry standards and propelling construction into a more advanced and prosperous future.

Read More

Revolutionary Light Frame Steel Machine Promises Next-Level Efficiency in Construction Industry

Title: Revolutionizing Construction: Light Frame Steel Technology Innovates the Building IndustryIntroduction:In a groundbreaking move towards transforming the construction industry, companies have introduced the cutting-edge Light Frame Steel Machine (LFSM). With its advanced technology and innovative features, the LFSM is revolutionizing the way buildings are designed and erected. This versatile tool stimulates sustainable practices, reduces construction time, and enhances structural stability. Combined with the expertise of industry-leading companies, the LFSM is paving the way for a new era of efficient and eco-friendly construction methods.I. The Advantages of Light Frame Steel Construction:Light frame steel construction has steadily gained popularity in recent years due to its numerous advantages. The LFSM harnesses these benefits and takes them to the next level, making it one of the most dominant techniques in the construction industry.1. Strength and Durability: Light frame steel structures offer superior strength and durability compared to traditional construction methods. The LFSM utilizes high-quality steel components that can withstand extreme weather conditions, seismic activities, and other potential hazards.2. Speed and Efficiency: The LFSM enables rapid construction by utilizing pre-engineered steel components that are cut precisely to size. This eliminates the need for on-site cutting and reduces construction time significantly. Additionally, the machine's automated capabilities streamline the entire process, further enhancing efficiency.3. Waste Reduction and Sustainability: Light frame steel construction generates minimal waste compared to traditional techniques. The LFSM optimizes material usage, resulting in cost savings and a reduced environmental impact. Additionally, steel is highly recyclable, promoting sustainable practices in the building industry.II. How the Light Frame Steel Machine Works:The Light Frame Steel Machine operates through a combination of advanced technology, engineering expertise, and automation. This state-of-the-art equipment seamlessly integrates into the construction process, ensuring precision and efficiency.1. Precision Engineering: The LFSM is designed to produce steel components with exceptional accuracy. The machine fabricates walls, floors, and roofs to precise specifications, guaranteeing a perfect fit during construction.2. Automated Production: The LFSM's automated features minimize human error and allow for large-scale production. The machines can be programmed to execute complex tasks, ensuring consistent quality while reducing labor costs.3. Versatile Design Capabilities: The LFSM is adaptable to a wide range of architectural designs, allowing for creative flexibility in building projects. From sleek modern structures to more traditional designs, the machine accommodates various configurations, ensuring every vision can be brought to life.III. Successful Implementation and Benefits for Companies:Leading companies in the construction industry have embraced the Light Frame Steel Machine and are experiencing the transformative benefits it offers.1. Enhanced Profitability: The LFSM delivers cost savings through reduced construction time and waste reduction. Its efficiency allows construction companies to take on more projects simultaneously, increasing profitability.2. Improved Safety: Light frame steel construction, coupled with the LFSM, enhances overall structural integrity. The steel components produced by the machine possess high fire resistance and are less susceptible to damage caused by pests or moisture, ensuring safer building environments.3. Sustainable Building Practices: The environmentally conscious nature of light frame steel construction aligns with the growing demand for sustainable buildings. Utilizing the LFSM helps companies establish a reputation for adopting green building practices, attracting environmentally conscious clients and bolstering brand value.Conclusion:The Light Frame Steel Machine revolutionizes construction practices through its advanced technology, precision engineering, and sustainability benefits. Its ability to enhance efficiency, reduce waste, and improve the structural integrity of buildings makes it an invaluable asset in the construction industry. With its adoption by prominent companies, this innovative machine is set to create a new era of efficient and eco-friendly construction methods, propelling the industry into a sustainable future.

Read More