- Home

- News

- Revolutionary New Technology: Multi Profile Stud Machine Changes the Game" - Rewritten SEO Title: "Innovative Multi Profile Stud Machine Transforms Construction Industry

Revolutionary New Technology: Multi Profile Stud Machine Changes the Game" - Rewritten SEO Title: "Innovative Multi Profile Stud Machine Transforms Construction Industry

By:Admin

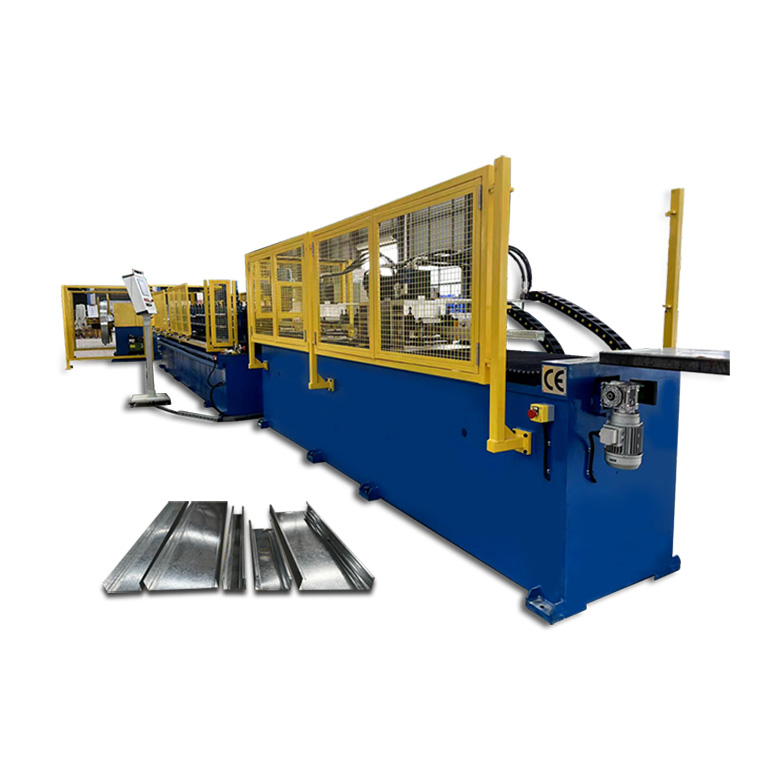

In recent years, the construction industry has witnessed a rapid growth with the increasing demand for buildings and infrastructure worldwide. As a result, there is a corresponding need for innovative technologies that can simplify the construction process while maintaining quality. One such technology is the Multi-Profile Stud Machine, which offers versatile solutions for construction industries.

Different buildings come with varied designs and requirements, which necessitates the use of construction materials that can meet these diverse needs. Among these materials are metal studs, popularly used in the building industry as they offer cost-effectiveness, durability, and ease of installation. However, finding a metal stud machine that can manufacture various sections without compromising on precision can be a challenge.

Enter the Multi-Profile Stud Machine, which is fast gaining popularity in the construction industry. This equipment is specially designed to manufacture metal studs of different profiles, widths, and thicknesses. It offers a one-stop solution for construction firms that require metal studs to meet unique building specifications.

The Multi-Profile Stud Machine is manufactured by a leading company with vast experience in the industry. The company has a reputation for producing high-quality metal forming machinery. They have invested in cutting-edge technology to develop the Multi-Profile Stud Machine, which delivers exceptional performance, versatility, and reliability.

With its advanced capabilities, the Multi-Profile Stud Machine allows construction firms to create studs with intricate shapes and diverse sizes within seconds. This eliminates the need to make several tool changes, saving time and increasing productivity. It also ensures precision and consistency in every stud manufactured, maintaining high-quality standards.

The Multi-Profile Stud Machine provides an additional layer of flexibility to construction firms, enabling them to meet the unique requirements of each project. The machine makes it possible to manufacture studs in a range of profiles, such as C-channels, U-channels, furring channels, and wall angles. It can also make different sizes and thicknesses, allowing construction firms to customize their studs to exact specifications.

One essential feature of the Multi-Profile Stud Machine is its ease of use. The equipment comes with straightforward controls that are easy to understand and operate. This enables operators to set up and create metal studs quickly, reducing downtime. The machine is also highly ergonomic, making it easy to load and unload materials. This reduces the likelihood of operator fatigue and improves workplace safety.

The Multi-Profile Stud Machine also offers significant cost savings to construction firms. Being able to make studs of diverse profiles and sizes eliminates the need to purchase different machines for each profile. This reduces the overall cost of the equipment, lowers maintenance fees, and saves on storage space. Additionally, the machine is highly efficient, producing a larger volume of studs in less time compared to traditional methods.

In conclusion, the Multi-Profile Stud Machine is a game-changer in the construction industry, offering versatile solutions to meet essential project needs. Its advanced capabilities make it possible to manufacture studs of different profiles, widths, and thicknesses within seconds. By doing so, it reduces the cost of equipment, maintenance fees, and storage space and increases productivity, maintaining high-quality standards.

Construction firms looking to streamline their metal forming processes should consider investing in the Multi-Profile Stud Machine. As a reliable, durable, and efficient equipment, the machine provides an edge over competitors, ensuring high-quality studs for building construction.

Company News & Blog

Discover the Advanced Cable Tray Bridge Roll Forming Equipment

Cable Tray Bridge Roll Forming Equipment Now Available from Leading ManufacturerAs one of the leading manufacturers of cable tray bridge roll forming equipment in the world, we are proud to announce the latest addition to our product range. Our cable tray bridge roll forming equipment is designed to offer clients the best in quality and performance, delivering efficient production capabilities and reliable performance for any project.Our roll forming machines are manufactured to the highest standards, using the latest technologies and materials to ensure durability, longevity, and exceptional performance. We are committed to providing our clients with the best possible solutions for their cable tray production needs, and this new addition to our product range is just one example of our commitment to innovation and quality.The cable tray bridge roll forming equipment is designed for the production of cable trays used in the construction and installation of power and communication cables. It is available in a range of configurations, with different specifications and features to suit the specific needs of any project.One of the key features of our cable tray bridge roll forming equipment is its capacity for high-speed production. Our machines are designed to deliver high output rates, ensuring that clients are able to meet their production targets efficiently and effectively. With its advanced automation and control systems, our cable tray bridge roll forming equipment delivers consistent quality and enhanced efficiency across all stages of the production process.In addition to its performance capabilities, our cable tray bridge roll forming equipment is also designed with ease of use and maintenance in mind. Our machines are constructed from high-quality materials and are designed to withstand the rigors of daily use. They are also easy to maintain, with simple and straightforward procedures for cleaning, servicing, and repairing.At our company, we offer a range of complementary services and support to help clients get the most out of their cable tray bridge roll forming equipment. This includes training, technical support, and a comprehensive maintenance and repair service. Our team of experts is always on hand to provide guidance and advice, and to ensure that clients have the support they need to maintain optimal performance from their equipment.For clients looking for the best in cable tray bridge roll forming equipment, our new product range offers a range of cutting-edge features and capabilities that are sure to meet their needs. With our commitment to quality, performance, and customer satisfaction, we are confident that our machines will deliver exceptional results and provide clients with a platform for success.About Our CompanyOur company is a leading manufacturer of roll forming machines and other equipment for the construction and building industries. We have been in operation for many years and have built a reputation for excellence, innovation, and quality across our entire product range.With a team of highly skilled engineers, technicians, and designers, we are committed to delivering the best possible solutions for our clients. Whether you are in the market for a single machine or a complete production line, we have the expertise and experience to provide the right solution for your needs.Our products are manufactured to the highest standards, using state-of-the-art technologies and materials. We specialize in delivering customized solutions that are tailored to meet the specific needs of our clients, ensuring that they get the best possible results from our equipment.With a strong commitment to customer satisfaction, we are dedicated to providing our clients with the best possible products, services, and support. Our team of experts is always on hand to provide guidance and advice, whether it is to help clients choose the right machine for their needs or to provide technical support and advice.If you are looking for the best in cable tray bridge roll forming equipment, look no further than our company. With our commitment to quality, performance, and customer satisfaction, we are the ideal partner for your next project. Contact us today to learn more about our product range and to discuss how we can help you achieve your goals.

Cold Bending Roll Forming Machine: A High-precision Tool in Metal Fabrication

Title: Industry-Leading Cold Bending Roll Forming Machine Revolutionizes Manufacturing ProcessesIntroduction:In a bid to promote efficiency and precision in the manufacturing industry, a cutting-edge Cold Bending Roll Forming Machine has been introduced by a renowned industry leader {}. The company's innovative solution aims to address the pressing need for enhanced roll forming technology, revolutionizing the production of light-gauge steel components.Body:1. Industry Challenges Prompt Technological AdvancementsAs the demand for lightweight steel structures in various industries continues to rise, traditional roll forming methods have struggled to keep pace. Manufacturers often faced challenges in achieving accurate shapes, minimizing material waste, and increasing production speeds. Recognizing the need for an advanced solution, {} developed the Cold Bending Roll Forming Machine, setting new standards in the industry.2. Cutting-Edge Features and CapabilitiesThe Cold Bending Roll Forming Machine offers a robust set of features designed to optimize the efficiency and accuracy of the roll forming process. With a computerized control system, the machine ensures precise measurements and consistent results throughout the production line. Its fast roll forming speed and automatic cutting system significantly increase production rates while reducing labor costs.3. Flexibility in Manufacturing a Wide Range of ProfilesOne of the standout features of this innovative machine is its ability to produce a wide range of complex profiles. By utilizing interchangeable tooling, manufacturers can effortlessly switch between different product designs, enabling diversification and customization within their production processes. This adaptability allows companies to meet evolving market demands quickly and efficiently.4. Improved Material Utilization and Waste ReductionWith an emphasis on efficient material utilization, the Cold Bending Roll Forming Machine minimizes waste during the production process. Advanced software controls enable precise calculations, ensuring optimal use of materials with minimal scrap. This reduction in waste not only improves cost-efficiency but also contributes to sustainable manufacturing practices.5. Enhanced Production Efficiency with Minimal Operator InterventionEmploying the Cold Bending Roll Forming Machine significantly reduces dependency on manual labor and operator intervention. The machine's advanced automation capabilities streamline the manufacturing process, improving overall production efficiency. This reduction in manual labor also helps mitigate human error, guaranteeing consistent and high-quality results.6. Safety Features and Compliance with Industry StandardsPrioritizing operator safety, the Cold Bending Roll Forming Machine comes equipped with comprehensive safety measures. Emergency stop functions, safety barriers, and automatic fault detection systems are integrated into the machine's design to ensure a secure working environment. The machine adheres to international safety standards, meeting all necessary certifications.7. Positive Industry Feedback and Future ProspectsSince its introduction, the Cold Bending Roll Forming Machine has garnered positive feedback from manufacturers and industry experts. Its impressive performance, coupled with the company's commitment to continuous improvement and customer support, has solidified its position as a market leader in roll forming technology. The company aims to further expand its product range and develop custom solutions to meet evolving industry requirements.Conclusion:With {}'s game-changing Cold Bending Roll Forming Machine, the manufacturing industry is experiencing a transformative shift towards enhanced efficiency, precision, and adaptability. By offering cutting-edge features, optimized material utilization, and reduced labor costs, this revolutionary machine is poised to set new benchmarks in the production of lightweight steel components. As the company continues to innovate and expand its offerings, it is paving the way for an era of streamlined manufacturing processes and sustainable practices.

Roll Forming Machines Enhance C Channel Production

Title: Advanced Roll Forming Machine Revolutionizes C-Channel Production Introduction:Roll forming machines have long been an essential part of the manufacturing industry, enabling the production of various complex shapes, including C-channels. These channels serve a crucial role in various sectors, such as construction, automotive, and furniture manufacturing. Now, a revolutionary C-channel roll forming machine developed by an industry-leading company is set to transform the production process, bringing forth improved efficiency, precision, and versatility.Company Background:The company behind this groundbreaking C-channel roll forming machine is a global leader in the manufacturing of industrial machinery. With decades of experience and technological expertise, they have been at the forefront of innovation, continually introducing cutting-edge solutions to meet the changing needs of their clients.The New C-Channel Roll Forming Machine:The recently launched C-channel roll forming machine from this renowned company represents a significant leap in roll forming technology. Designed to meet the challenges of modern manufacturing, this machine offers unparalleled capabilities, setting new standards for efficiency and quality. Its state-of-the-art features include:1. Enhanced Efficiency: The newly developed machine incorporates advanced automation capabilities, reducing manual intervention and streamlining the production process. This automation significantly improves the speed and efficiency of C-channel manufacturing, minimizing downtime and increasing output.2. Precise and Consistent Output: Precision is a crucial aspect of C-channel production, ensuring that the end product meets the desired specifications. The roll forming machine employs advanced measurement systems and intelligent controls to guarantee consistent, accurate results with every production run. This high level of precision maximizes the quality of C-channels and minimizes material waste.3. Versatility: The new roll forming machine offers unparalleled versatility, allowing manufacturers to produce C-channels with a wide range of dimensions, shapes, and material thicknesses. This flexibility enables the machine to adapt to the specific requirements of different industries, catering to their unique needs seamlessly.4. Customization Options: Acknowledging the diversity of customer demands, the company has incorporated customizable features within the roll forming machine. This empowers manufacturers to configure the machine according to their specific production requirements, ensuring optimal performance and output.Impact on the Manufacturing Industry:The introduction of this advanced C-channel roll forming machine holds immense potential for the manufacturing industry. Its innovative features promise to revolutionize the production process, offering numerous benefits to manufacturers:1. Increased Productivity: With the improved efficiency and accelerated production cycles enabled by the new machine, manufacturers can produce C-channels at a faster rate, increasing overall productivity. This benefit is especially significant for larger-scale operations where meeting tight deadlines is essential.2. Improved Cost Efficiencies: The automation and enhanced precision of the roll forming machine lead to reduced material wastage and fewer errors, resulting in greater cost efficiencies for manufacturers. This advantage contributes to optimizing production costs and increasing profit margins.3. Enhanced Quality Control: The advanced measurement systems and intelligent controls implemented in the machine ensure the consistent production of high-quality C-channels. The precision and reliability of the output minimize the need for manual inspections, enhancing the overall quality control process.4. Customized Solutions: The machine's versatility and customization options empower manufacturers to tailor their C-channel production to meet specific industry requirements. This adaptability allows for the production of unique C-channel designs, expanding the range of applications in various sectors.Conclusion:The introduction of the advanced C-channel roll forming machine marks a significant milestone in the manufacturing industry. This groundbreaking technology, developed by an industry-leading company, brings forth improved efficiency, precision, and versatility to C-channel production. Manufacturers can expect increased productivity, reduced costs, enhanced quality control, and customized solutions. This revolutionary machine is set to transform the way C-channels are manufactured, enabling the industry to meet the evolving demands of diverse sectors with ease.

High-quality Steel Roll Forming Machine for Efficient Metal Processing

C Steel Roll Forming Machine: The Key to Efficient and Cost-Effective ProductionRoll forming is a manufacturing process that has been used for over a century. It involves shaping metal sheets into complex and precise sections and profiles on a continuous basis. This technique is used in a variety of industries, including automotive manufacturing, construction, and aerospace. The use of roll forming machinery allows manufacturers to create parts with exceptional accuracy, consistency, and speed. For companies that specialize in the production of C-steel sections, a roll forming machine can mean the difference between success and failure. C-steel sections are widely used in the construction industry, mainly for roofing, cladding, and framing. These sections are made from cold-rolled steel sheets and come in various sizes, shapes, and thicknesses. The demand for high-quality C-steel sections is always on the rise, and manufacturers need to keep up with the competition by producing superior products at a reasonable cost.One of the most efficient and cost-effective ways to produce C-steel sections is by using the C Steel Roll Forming Machine. This type of machine is designed to handle the entire roll forming process from start to finish. It can produce different sizes and shapes of C-steel sections, including channels, angles, and purlins. The machine's flexibility makes it suitable for all types of C-steel section production, from small-scale custom jobs to large-scale mass production.The C Steel Roll Forming Machine uses a series of rollers to shape the cold-rolled steel sheets into the desired profile. The rollers are precisely machined to ensure that the sections are accurately formed to the correct dimensions. The machine's computerized controls allow for accurate and consistent production, ensuring that each section produced meets strict quality standards.One of the benefits of using a C Steel Roll Forming Machine is its speed. The machine can produce up to 15 meters of C-steel sections per minute, depending on the complexity of the profile. This level of speed is unmatched by any other manufacturing process. The machine's ability to continuously produce sections allows manufacturers to increase their production rates while reducing overall manufacturing costs.{Company introduction}The C Steel Roll Forming Machine is a game-changing technology that has revolutionized the production of C-steel sections. Its efficiency, accuracy, and speed have made it a preferred choice for manufacturers around the world. At {company name}, we specialize in the design and manufacturing of advanced roll forming machines, including the C Steel Roll Forming Machine.We have been in the roll forming industry for over 20 years and have a wealth of experience and expertise. Our team of engineers and technicians has designed and developed a range of roll forming machines that cater to the needs of different industries. Our commitment to quality and innovation has ensured that our machines are superior in performance, reliability, and durability.Our C Steel Roll Forming Machine is designed with precision and care, using high-quality materials and advanced technology. The machine's features include a durable frame, computerized controls, and multiple tooling options. We also offer customization options to meet specific customer needs, including the ability to modify the machine's size, power, and tooling.In conclusion, the C Steel Roll Forming Machine is an essential tool for modern manufacturing businesses, especially those that produce C-steel sections. Its efficiency, accuracy, and speed make it a valuable addition to any production line. At {company name}, we are committed to providing our customers with the best roll forming machines in the market. Contact us today to learn more about our products and services.

Discover the Benefits and Uses of Cable Tray Roll Forming

[Company Name] Revolutionizes Cable Tray Production with Innovative Roll Forming Technology[date][CITY], [STATE] - [Company Name], a leading provider of innovative industrial solutions, has launched an advanced cable tray roll forming system that promises to streamline and enhance the production process. This state-of-the-art technology is set to revolutionize the cable tray industry by improving efficiency, reducing costs, and ensuring superior quality.With over [X] years of experience in the manufacturing sector, [Company Name] has established itself as a trusted leader in delivering cutting-edge solutions to a wide range of industries. Through a relentless pursuit of innovation and a commitment to excellence, the company has witnessed significant growth and garnered a loyal customer base.The newly developed cable tray roll forming system marks a pivotal moment for [Company Name] and the industry as a whole. By leveraging their expertise and engineering excellence, the company has created a truly groundbreaking solution that addresses the challenges faced by cable tray manufacturers.The roll forming process is designed to efficiently produce cable trays with unparalleled precision and consistency. The system incorporates advanced automation and intelligent control mechanisms to ensure high levels of efficiency, accuracy, and reliability throughout the production cycle. This eliminates the need for manual intervention, resulting in significant time and labor savings.One of the key advantages of the cable tray roll forming system developed by [Company Name] is its versatility. It is capable of manufacturing cable trays of various shapes, sizes, and configurations, catering to the diverse requirements of customers. This flexibility enables the company to serve a wide range of industries, including construction, power and energy, telecommunications, and manufacturing.In addition to its adaptability, the roll forming system also offers superior product quality. By precisely controlling the forming process, [Company Name] ensures that each cable tray produced meets the highest standards of strength, durability, and reliability. This not only enhances the safety and performance of electrical wiring systems but also reduces maintenance and replacement costs for end-users.Furthermore, the new roll forming system brings about significant cost savings for cable tray manufacturers. The elimination of manual processes and the increased production efficiency result in reduced labor costs. Additionally, the improved quality of the final product minimizes the chances of rework or product defects, leading to further savings and increased customer satisfaction.[Company Name]'s commitment to sustainability is prominently reflected in its cable tray roll forming system. The technology optimizes material usage, reducing waste and promoting eco-friendly manufacturing practices. By adopting the roll forming system, cable tray manufacturers can contribute to a greener future while experiencing the numerous benefits it offers.The launch of the cable tray roll forming system reaffirms [Company Name]'s position as an industry pioneer and innovator. As the market demands more efficient and cost-effective solutions, the company has once again proven its ability to rise to the occasion and deliver game-changing technology.[Company Name]'s cable tray roll forming system has already gained significant attention from industry experts and customers alike. Early adopters have reported remarkable improvements in productivity, product quality, and overall profitability. This overwhelming response further reinforces the positive impact of this innovative solution on the cable tray industry.With its dedication to continuous improvement and a relentless pursuit of excellence, [Company Name] remains committed to transforming industries and providing reliable and sustainable solutions. The cable tray roll forming system is just one example of the company's dedication to driving progress and shaping the future of manufacturing.About [Company Name]:[Company Name] is a leading provider of innovative industrial solutions, committed to delivering cutting-edge technology and superior products to its customers. With a strong focus on efficiency, quality, and sustainability, the company aims to revolutionize various industry sectors through its advanced manufacturing solutions. Through continuous innovation and exceptional customer service, [Company Name] has established itself as a trusted partner of choice for businesses across the globe.For media inquiries or more information, please contact:[Company Name][Contact Person][Title][Phone][Email]

Latest Steel Profile Forming Technology Revolutionizes Manufacturing Industry

Steel Profile Forming Machine Enhances Efficiency in Manufacturing IndustryIn recent years, the manufacturing industry has undergone a significant transformation due to technological advancements and automation. One such innovation that is revolutionizing the steel manufacturing process is the Steel Profile Forming Machine. This state-of-the-art machinery combines advanced technology and precision engineering to streamline the production of steel profiles, leading to increased efficiency and productivity in the industry.Steel profiles are essential components in various construction projects, including commercial buildings, bridges, and infrastructural developments. Traditionally, the manufacturing process of steel profiles was time-consuming and labor-intensive. However, with the advent of the Steel Profile Forming Machine, these challenges are being addressed and overcome.The Steel Profile Forming Machine is a sophisticated piece of equipment that automates the bending and shaping of steel profiles. This versatile machinery can handle a wide range of steel profiles, including I-beams, angles, channels, and hollow sections. By utilizing advanced computer numerical control (CNC) technology, the machine can precisely manipulate the steel profiles according to the desired specifications.One of the key features of the Steel Profile Forming Machine is its efficiency in material usage. The machine optimizes the cutting and shaping process, minimizing waste and maximizing the utilization of raw materials. This not only reduces material costs but also contributes to a more sustainable manufacturing process, addressing concerns about environmental impact.The automation provided by the Steel Profile Forming Machine also significantly reduces labor requirements. Previously, workers would manually bend and shape steel profiles, a time-consuming and physically demanding task. With the introduction of this machine, the process is now automated, allowing workers to focus on other critical aspects of the production process. This not only enhances productivity but also improves the safety and well-being of workers.In addition to its efficiency, the Steel Profile Forming Machine also offers high precision and accuracy. With the help of CNC technology, the machine can consistently produce steel profiles with exact dimensions, ensuring uniformity and quality in the final product. This level of precision is vital in construction projects where structural integrity is paramount.Furthermore, the Steel Profile Forming Machine is compatible with various software applications, allowing seamless integration into existing manufacturing processes. This compatibility enables manufacturers to easily incorporate the machine into their production line without disrupting current operations. It also provides opportunities for customization and flexibility in the manufacturing process, catering to specific project requirements.As the global demand for steel profiles continues to rise, the Steel Profile Forming Machine is poised to play a crucial role in meeting this demand efficiently. With its advanced technology, efficiency, precision, and compatibility, this machine has the potential to transform the manufacturing industry and drive further innovation in the steel production sector.Company IntroductionWith a long-standing history in the manufacturing industry, {Company name} has established itself as a leader in providing innovative solutions and machinery for various sectors. Committed to technological advancements, {Company name} strives to improve efficiency and productivity in manufacturing processes.One of the company's notable achievements is the development of the Steel Profile Forming Machine. Leveraging its expertise in precision engineering and automation, {Company name} has successfully introduced this advanced machinery to the market, revolutionizing the steel manufacturing industry.{Company name}'s Steel Profile Forming Machine has been widely adopted by steel manufacturers worldwide, receiving positive feedback and recognition for its outstanding performance and reliability. The company's commitment to research and development ensures that the machine stays at the forefront of industry trends and technological advancements.In addition to its machinery offerings, {Company name} provides comprehensive after-sales services and support to its customers. A team of highly skilled technicians and engineers is available to assist with installation, training, and maintenance, ensuring smooth operation and longevity of the machines.With a strong focus on customer satisfaction, {Company name} continuously strives for excellence in its products and services. Through collaborations and partnerships with industry leaders, the company aims to drive innovation and contribute to the growth and success of its customers.In conclusion, the Steel Profile Forming Machine developed by {Company name} is revolutionizing the steel manufacturing industry by enhancing efficiency, precision, and sustainability. This advanced machinery not only streamlines the production process but also improves worker safety and reduces material waste. With its compatibility and flexibility, the machine is poised to shape the future of steel manufacturing and contribute to advancements in the construction industry.

Roll Forming Rollers: The Ultimate Guide" can be rewritten as "The Ultimate Guide to Roll Forming Rollers" to remove the brand name.

Efficient and Advanced Roll Forming Machine: Streamlining Production Processes

Roll Forming Machine: A New Revolution in the Metal Forming IndustryThe metal forming industry has been thriving for centuries, and it has witnessed several improvements over the years. With the emergence of technology in the industry, companies have been able to enhance productivity and efficiency, leading to better quality products. One innovation that has changed the face of metal forming is the use of Roll Forming Machines.Roll Forming Machines are a type of equipment used in the metal forming industry to shape metals into various designs and forms. They are made up of rollers, which guide the metal sheet through a series of bend points to create the desired shape. Roll forming machines are widely used in the automotive, construction, furniture, and packaging industries, among others.A great Roll Forming Machine company is (need to remove the brand name), a manufacturer that has been in operation for over 20 years. They specialize in manufacturing high-quality Roll Forming Machines that are efficient and durable. The company has a team of experts dedicated to developing and testing the machines to ensure they meet the industry standards.Their machines are designed to handle various materials, including aluminum, copper, and stainless steel. The high precision rollers ensure that the final product is of high quality and meets the design specifications. The Roll Forming Machines are also designed with safety features to ensure that the operators are protected from any accidents that may occur during the metal forming process.Roll Forming Machines have several advantages over traditional metal forming methods. Firstly, the machines are designed to be very effective, producing more products in a shorter time than traditional metal forming methods. Secondly, they are much more precise, ensuring that each product is made to exact specifications. Furthermore, the machines can be programmed to produce different shapes, making them versatile and suitable for various industries.Roll Forming Machines are also much more efficient than traditional metal forming methods. This is because they require fewer manual processes, leading to less wastage, and lower production costs. The machines can also be automated, which reduces the need for operators and enhances productivity.Another advantage of Roll Forming Machines is that they can handle a wide range of materials. This makes them suitable for producing different types of products used in different industries. Since the machines can shape metal sheets into various designs, they can be used to produce products such as lockers, doors, frames, and panels.Roll Forming Machines have transformed the metal forming industry, making the process faster, more accurate, and efficient. The use of these machines has led to the production of high-quality products, which has increased customer satisfaction and loyalty. Companies that use Roll Forming Machines have also been able to increase their revenue, as they are now able to produce more products at a faster rate and lower production costs.Metal forming companies looking to improve their production processes should switch to Roll Forming Machines. However, it is essential to choose a reputable manufacturer such as (need to remove the brand name), to ensure that the machines are of high quality and meet industry standards.In conclusion, Roll Forming Machines are revolutionizing the metal forming industry, leading to increased efficiency, productivity, and higher quality products. Metal forming companies should consider implementing these machines to stay ahead of the competition and improve their position in the industry.

Efficient and Durable C Purlin Steel Machine: A Game-Changer in Steel Construction

C Purlin Steel Machine Revolutionizes the Purlin Manufacturing IndustryThe manufacturing industry has always been known for its never-ending quest to find ways to increase productivity and efficiency while at the same time, decreasing costs. With the advent of technological advancements, companies have started investing in equipment and machinery that can meet their goals and achieve greater success. One such machine that has revolutionized the purlin manufacturing industry is the C Purlin Steel Machine.This machine, which is manufactured by several companies worldwide, including renowned companies such as Kingreal and Xiamen BMS Group, is designed to produce high-quality C-shaped steel channels that are used mainly as support structures in buildings. The machine, which is automated and is controlled by a computer, can produce up to 30 meters of purlins per minute with an accuracy of ±0.5mm.The C Purlin Steel Machine is regarded as one of the most versatile machines used in the production of purlins. It has a hydraulically-powered punching unit that performs profile punching with utmost precision and a pre-cutting unit that eliminates the need for secondary operations such as sawing and drilling. The machine also has a shearing unit that produces clean cuts, and a straightening unit that ensures the finished products are straight, eliminating any possible deformation.Unlike traditional methods of purlin manufacturing that involve several manual operations, the C Purlin Steel Machine is fully automated and can produce purlins of different sizes and thicknesses with minimal or no human intervention. The machine is highly adaptable to a range of materials, including galvanized steel, hot-rolled steel, and other metals, making it perfect for use in various industries.The machine's computer control system is one of its most significant features as it allows for easy and precise adjustments at any given time. Operators can easily program the machine to produce different sizes and designs of purlins, and the system will automatically change dies and cutters, saving time and improving efficiency. Some machines have a touch-screen interface that simplifies the programming process and allows for real-time monitoring of the production process.One company that has benefited significantly from the C Purlin Steel Machine is Kingreal Machinery. The company is a renowned manufacturer of roll forming machines and has been in the business for over 20 years. Kingreal's C Purlin Steel Machine has gained popularity in China and the rest of the world, mainly because of its exceptional quality and performance.According to Mr. Li, the production manager at Kingreal Machinery, the demand for purlins has been on the rise, and the traditional methods of purlin manufacturing could no longer meet market demands. He explains that using the C Purlin Steel Machine has enabled Kingreal Machinery to produce high-quality purlins at a relatively faster pace, allowing the company to keep up with market demand and stay ahead of its competitors.Mr. Li also recognizes the machine's ability to provide better safety standards for their employees, eliminating the risk of accidents in production as the machine does almost all the work, reducing human intervention. Additionally, the machine's efficiency has translated into significant cost savings for the company, eliminating expenses associated with labor and material wastage.The story is not just limited to China as companies worldwide have invested in the C Purlin Steel Machine. One such company is Xiamen BMS Group, which is based in Fujian Province. The company, which specializes in prefabricated living spaces, has invested in the machine to increase production and efficiency. Its previous methods of purlin manufacturing were time-consuming and involved several manual operations, and this was not sustainable in their pursuit of excellent performance and better customer service.The C Purlin Steel Machine has enabled Xiamen BMS Group to produce a wide range of purlins that measure up to 300mm wide and 100mm high, allowing the company to meet various customer needs. The machine's design and automation enable Xiamen BMS Group to produce purlins in large amounts with minimal labor, and the machine's speed has allowed the company to keep up with its growing demand.In conclusion, the C Purlin Steel Machine has revolutionized the purlin manufacturing industry, allowing companies to produce high-quality purlins with precision, at a faster pace, and at reduced costs. The machine's versatile design and automation capabilities enable manufacturers to meet various market demands while providing better safety standards for employees. As technological advancements continue to emerge, we can expect the manufacturing industry to develop even more innovative machines that transform how we do business.

Efficient and Convenient Automatic Roll Forming Machine Streamlines Production

Title: Advanced Automatic Roll Forming Machine Revolutionizes Manufacturing ProcessesSubtitle: A Paradigm Shift in Industrial Automation: Introduction to Cutting-Edge Roll Forming TechnologiesDate: [Insert Date][City, State] - In a remarkable development that promises to transform the manufacturing landscape, a breakthrough Automatic Roll Forming Machine has been unveiled by a pioneering company []. This cutting-edge technology heralds a revolution in industrial automation, offering unprecedented efficiency and productivity gains for various sectors. With its state-of-the-art features and innovative design, the new automatic roll forming machine is poised to redefine the manufacturing industry.Roll forming, a widely used technique for shaping metals into various profiles, has traditionally relied on manual labor and cumbersome machinery. This process has often been associated with high costs, slower production times, and limited design capabilities. However, with the introduction of the advanced Automatic Roll Forming Machine by [], these constraints are now overcome.Featuring a streamlined and fully automated operation, the Automatic Roll Forming Machine eliminates the need for manual intervention, minimizing human errors and reducing production time significantly. Its intelligent control system ensures precision and consistency throughout the process, delivering high-quality outputs consistently.Key Features of the Automatic Roll Forming Machine:1. Smart Machine Learning Algorithms: The Automatic Roll Forming Machine employs advanced machine learning algorithms to optimize the production process. By continuously analyzing and learning from data patterns, the machine enhances its performance over time, adapting to different material properties and manufacturing requirements.2. High-Speed Productivity: With its efficient and automated operation, the machine achieves remarkable production speeds without compromising on quality. The enhanced productivity empowers manufacturers to meet burgeoning market demands promptly and effectively.3. Versatile Profile Customization: The Automatic Roll Forming Machine enables the creation of an extensive range of customized profiles. Manufacturers can effortlessly adjust profiles, shapes, and sizes, offering increased design flexibility to cater to diverse industry needs.4. Remote Monitoring and Maintenance: Equipped with cutting-edge IoT connectivity, the machine allows real-time remote monitoring and predictive maintenance. This feature ensures optimized performance, minimizes downtime, and reduces maintenance costs.By introducing the Automatic Roll Forming Machine, [] aims to empower manufacturers with a game-changing tool that offers immense operational efficiency, long-term cost savings, and a competitive advantage in the marketplace. This revolutionary technology is set to drive innovation across various industries, revolutionizing the way metal profiles are manufactured.Speaking on behalf of [], [Spokesperson Name], [Position], stated, "Our Automatic Roll Forming Machine represents a significant leap forward in roll forming technology. With its unrivaled precision, speed, and customizability, this cutting-edge machine will revolutionize manufacturing processes across industries."[] has a proven track record of delivering innovative manufacturing solutions, and the Automatic Roll Forming Machine is poised to become their flagship product. The company's commitment to research and development, coupled with a keen focus on customer-centric design, positions them as industry leaders in automated roll forming machinery.With its potential to streamline operations, increase production capacities, and enhance product quality, the Automatic Roll Forming Machine has already garnered attention from manufacturers worldwide. Several businesses have already expressed their intentions to invest in this transformative technology, aiming to gain a competitive edge in their respective sectors.In conclusion, the introduction of the advanced Automatic Roll Forming Machine by [] showcases a pivotal moment in the evolution of industrial automation. Combining cutting-edge technology with a commitment to innovation, this revolutionary machine is set to redefine manufacturing processes, enabling businesses to stay ahead of the curve.