- Home

- News

- Discover the Advantages of Cold Roll Forming Technology for Efficient Metal Fabrication Processes

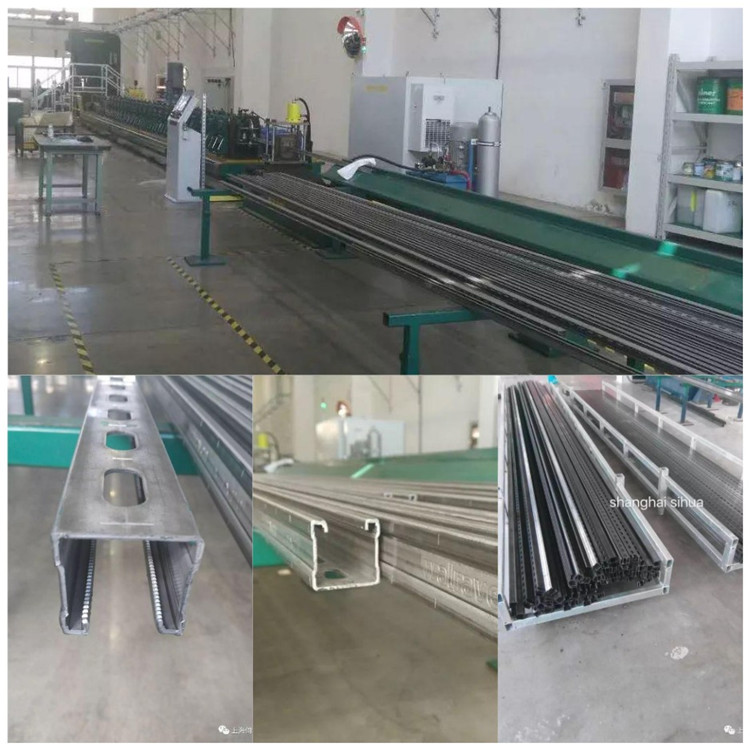

Discover the Advantages of Cold Roll Forming Technology for Efficient Metal Fabrication Processes

By:Admin

[City, Date] - [Company Name], a leading manufacturer in the cold roll forming industry, is revolutionizing the manufacturing process with its latest advanced technology. Developed in-house by their team of experts, the new cold roll forming technology is set to enhance production capabilities and provide superior quality products.

Cold roll forming is a highly efficient and versatile metal forming process used in a wide range of industries. It involves continuously bending a long strip of metal through a series of roll stands to achieve a desired shape and profile. This method offers significant advantages over traditional hot rolling, as it enables precise control of metal thickness, complex shapes, and consistent high-quality results.

[Company Name] has been at the forefront of the cold roll forming industry for several years, offering innovative solutions to meet the varying needs of its customers. With the introduction of their latest technology, the company is once again pushing the boundaries of what can be achieved through cold roll forming.

One of the key features of this new technology is its advanced control system, which allows for real-time monitoring and adjustment of the roll forming process. By constantly analyzing data and making instant adjustments, [Company Name] ensures precise and accurate shaping of metal profiles, minimizing material waste and maintaining consistent quality throughout production.

In addition, the new technology incorporates state-of-the-art sensors and measurement devices to ensure optimal performance. These sensors provide accurate readings of various parameters such as thickness, width, and curvature, allowing for seamless control and improved efficiency. The collected data is also used for further analysis and optimization of the entire manufacturing process.

With this advanced cold roll forming technology, [Company Name] is able to offer its customers a wider range of options and possibilities. The flexibility of the process allows for the production of complex and intricate profiles, meeting the most challenging design requirements. Whether it's creating custom shapes for the automotive industry or manufacturing precise components for the construction sector, [Company Name] is well-equipped to cater to diverse market demands.

"We are thrilled to introduce our latest cold roll forming technology to the industry," said [Company Name]'s CEO. "This innovation represents a significant milestone in our ongoing commitment to providing cutting-edge solutions and exceptional quality to our customers. We believe that this technology will revolutionize the way metal profiles are manufactured, opening up new opportunities and setting new standards in the industry."

To ensure seamless integration of the new technology, [Company Name] has also invested in training its workforce. Employees have undergone extensive training programs to fully understand and operate the advanced control system and other features of the technology. This enables the company to maintain high standards of performance, efficiency, and quality across all aspects of its operations.

As [Company Name] continues to lead the way in the cold roll forming industry, this new technology further establishes their position as a trusted and innovative manufacturer. With enhanced capabilities and a strong focus on quality, the company is prepared to meet the evolving needs of customers and provide reliable solutions for diverse applications.

About [Company Name]:

[Company Name] is a renowned manufacturer in the cold roll forming industry, specializing in the production of high-quality metal profiles for various sectors. With a commitment to innovation and superior customer service, the company has earned a reputation for delivering reliable solutions that meet the highest standards.

Company News & Blog

How to Roll Form C Purlins for Your Construction Project

Roll forming technology has become an essential part of modern construction. It provides durable and flexible solutions that can be customized to match various building requirements. One of the most popular roll-formed products is the C Purlin, which has found wide applications in commercial and industrial construction.C Purlin roll forming involves the continuous bending of a flat strip of sheet metal into the shape of a C section. The process is carried out by a set of rolls that progressively twist the strip until it forms the correct profile. The resultant product is strong, lightweight, and has high load-bearing capacity, making it ideal for many applications such as roofing, cladding, and support structures.One notable company that provides C Purlin roll forming services is (need remove brand name), a leading manufacturer of roll-formed steel products. With over 30 years of experience, the company has built a strong reputation for quality, reliability, and excellent customer service. They operate from a state-of-the-art manufacturing facility that employs the latest technology and best practices to deliver superior products.In addition to C Purlin, (need remove brand name) offers a range of other roll-formed products such as Z Purlin, U channel, stud and track, and metal decking. They also provide custom solutions to meet specific customer needs. Their products are used in a variety of industries such as agriculture, construction, and transportation.One of the reasons why (need remove brand name) has been successful in the roll forming industry is their commitment to quality. They use only high-grade steel and follow strict quality control procedures at every stage of the manufacturing process. Their products are tested and inspected to ensure they meet or exceed industry standards.Another factor that sets (need remove brand name) apart is their fast turnaround time. They have a large inventory of raw materials and finished products, which enables them to fulfill orders quickly and efficiently. They also have a dedicated logistics department that ensures timely delivery of products to customers.Customer satisfaction is also a top priority for (need remove brand name). They work closely with customers to understand their needs and provide customized solutions that meet their specific requirements. They also offer technical support and advice to ensure customers get the most out of their products.The company has invested heavily in research and development to stay abreast of the latest trends and technologies in the roll forming industry. They have a team of experienced engineers and designers who are constantly innovating and creating new products that meet the changing needs of the market.Furthermore, (need remove brand name) is committed to environmental sustainability. They have implemented several initiatives to reduce their carbon footprint and conserve natural resources. Their manufacturing process is designed to minimize waste and emissions, and they use eco-friendly packaging materials.In conclusion, roll forming technology is an integral part of modern construction, and C Purlin is one of the most popular roll-formed products. Companies like (need remove brand name) have played a significant role in providing quality products and services to the industry. With their commitment to quality, customer service, innovation, and sustainability, they are well-positioned to continue to lead the roll forming industry into the future.

Roll Forming Machines for C Purlins: A Guide to Cost-Effective Manufacturing

Title: Advanced C Purlin Roll Forming Technology Empowers the Steel Industry[City], [Date] - [Company Name], a leading innovator in roll forming machinery, is revolutionizing the steel industry with its advanced C Purlin Roll Forming technology. This state-of-the-art equipment is reshaping the way steel structures are manufactured, making the process faster, more efficient, and cost-effective.C Purlins are widely used in the construction industry to provide structural support and distribute loads in buildings, especially those with large spans. Traditionally, manufacturing C Purlins involved labor-intensive processes, resulting in longer lead times, high material wastage, and potential inconsistencies in product quality. However, [Company Name]'s groundbreaking roll forming technology has addressed these drawbacks, raising the bar for the entire steel industry.The innovative C Purlin Roll Forming technology developed by [Company Name] utilizes computerized control systems, precision engineering, and an optimized workflow to streamline the entire manufacturing process. Through a series of automated steps, raw steel coils are transformed into high-quality C Purlins with precise dimensions and exceptional strength.One of the key advantages of [Company Name]'s technology is its ability to minimize material wastage. By using intelligent cutting mechanisms, the roll forming machines accurately cut the steel coils to size, minimizing scrap material and reducing costs. Additionally, the automated nature of the process drastically reduces human error in manufacturing, ensuring consistent product quality and improving overall efficiency.Furthermore, the advanced computerized control system allows for precise customization of C Purlins, enabling manufacturers to produce a wide range of sizes and configurations tailored to specific project requirements. This flexibility enhances the suitability of C Purlins for various applications, from small-scale residential projects to large industrial structures.In comparison to traditional manufacturing methods, [Company Name]'s C Purlin Roll Forming technology significantly reduces lead times. The automated production line works at a high speed, efficiently transforming steel coils into finished C Purlins. This shorter production time translates into quicker project turnaround, enabling construction companies to meet tight schedules and minimize costs associated with extended construction periods.The increased speed and efficiency of [Company Name]'s technology also contribute to a greener manufacturing process. By optimizing material usage and minimizing waste, the carbon footprint associated with C Purlin production is reduced compared to conventional methods. This environmentally friendly approach aligns with [Company Name]'s commitment to sustainable and responsible manufacturing practices.In addition to the advanced technology, [Company Name] prides itself on its comprehensive customer support and service. With a dedicated team of experts, the company ensures smooth installation and maintenance of their roll forming machines, minimizing downtime and maximizing productivity for their clients. [Company Name] also provides training programs to help manufacturers leverage the full potential of their roll forming equipment.The impact of [Company Name]'s C Purlin Roll Forming technology is revolutionizing the steel industry, allowing manufacturers to produce high-quality C Purlins with exceptional speed, precision, and cost-effectiveness. As construction demands continue to grow worldwide, [Company Name] remains at the forefront of innovation, driving progress and reshaping the future of steel manufacturing.About [Company Name]:[Company Name] is a renowned global leader in the development and manufacturing of roll forming machinery. With a history of excellence spanning over decades, the company is committed to delivering cutting-edge solutions and providing unparalleled support to its valued customers. [Company Name]'s roll forming technology has been widely adopted by the steel industry, setting new benchmarks for efficiency, productivity, and sustainability.

Roll Forming Rollers: The Ultimate Guide" can be rewritten as "The Ultimate Guide to Roll Forming Rollers" to remove the brand name.

Cold Bending Roll Forming Machine: A High-precision Tool in Metal Fabrication

Title: Industry-Leading Cold Bending Roll Forming Machine Revolutionizes Manufacturing ProcessesIntroduction:In a bid to promote efficiency and precision in the manufacturing industry, a cutting-edge Cold Bending Roll Forming Machine has been introduced by a renowned industry leader {}. The company's innovative solution aims to address the pressing need for enhanced roll forming technology, revolutionizing the production of light-gauge steel components.Body:1. Industry Challenges Prompt Technological AdvancementsAs the demand for lightweight steel structures in various industries continues to rise, traditional roll forming methods have struggled to keep pace. Manufacturers often faced challenges in achieving accurate shapes, minimizing material waste, and increasing production speeds. Recognizing the need for an advanced solution, {} developed the Cold Bending Roll Forming Machine, setting new standards in the industry.2. Cutting-Edge Features and CapabilitiesThe Cold Bending Roll Forming Machine offers a robust set of features designed to optimize the efficiency and accuracy of the roll forming process. With a computerized control system, the machine ensures precise measurements and consistent results throughout the production line. Its fast roll forming speed and automatic cutting system significantly increase production rates while reducing labor costs.3. Flexibility in Manufacturing a Wide Range of ProfilesOne of the standout features of this innovative machine is its ability to produce a wide range of complex profiles. By utilizing interchangeable tooling, manufacturers can effortlessly switch between different product designs, enabling diversification and customization within their production processes. This adaptability allows companies to meet evolving market demands quickly and efficiently.4. Improved Material Utilization and Waste ReductionWith an emphasis on efficient material utilization, the Cold Bending Roll Forming Machine minimizes waste during the production process. Advanced software controls enable precise calculations, ensuring optimal use of materials with minimal scrap. This reduction in waste not only improves cost-efficiency but also contributes to sustainable manufacturing practices.5. Enhanced Production Efficiency with Minimal Operator InterventionEmploying the Cold Bending Roll Forming Machine significantly reduces dependency on manual labor and operator intervention. The machine's advanced automation capabilities streamline the manufacturing process, improving overall production efficiency. This reduction in manual labor also helps mitigate human error, guaranteeing consistent and high-quality results.6. Safety Features and Compliance with Industry StandardsPrioritizing operator safety, the Cold Bending Roll Forming Machine comes equipped with comprehensive safety measures. Emergency stop functions, safety barriers, and automatic fault detection systems are integrated into the machine's design to ensure a secure working environment. The machine adheres to international safety standards, meeting all necessary certifications.7. Positive Industry Feedback and Future ProspectsSince its introduction, the Cold Bending Roll Forming Machine has garnered positive feedback from manufacturers and industry experts. Its impressive performance, coupled with the company's commitment to continuous improvement and customer support, has solidified its position as a market leader in roll forming technology. The company aims to further expand its product range and develop custom solutions to meet evolving industry requirements.Conclusion:With {}'s game-changing Cold Bending Roll Forming Machine, the manufacturing industry is experiencing a transformative shift towards enhanced efficiency, precision, and adaptability. By offering cutting-edge features, optimized material utilization, and reduced labor costs, this revolutionary machine is poised to set new benchmarks in the production of lightweight steel components. As the company continues to innovate and expand its offerings, it is paving the way for an era of streamlined manufacturing processes and sustainable practices.

Unlocking the Potential of Track Roll Forming Machines: A Comprehensive Guide

Title: Advanced Roll Forming Machine Revolutionizing the Manufacturing SectorIntroduction:In recent years, the manufacturing industry has witnessed significant advancements in technology that have revolutionized production processes. One such innovation making waves is the latest track roll forming machine developed by a leading industry player. This cutting-edge machinery promises to streamline manufacturing operations, enhance efficiency, and deliver high-quality products. Let's delve into the features and benefits of this innovative solution that is set to redefine the roll forming industry.Body:1. Introduction to Roll Forming Technology:Roll forming is a widely used process in the manufacturing sector, especially for producing long metal strips with consistent cross-sections. Traditionally, this technique involves a sequence of bending, stamping, and cutting operations, which can be time-consuming and labor-intensive. To address these challenges, the roll forming industry has experienced a paradigm shift due to the introduction of advanced track roll forming machines.2. The Role of Advanced Track Roll Forming Machine in Streamlining Production:The brand-new track roll forming machine, developed by a leading manufacturing and engineering company, is designed to meet the growing demand for automated and efficient production processes. This innovative machine boasts several features that make it an indispensable tool for manufacturers, including:a. High-speed Production: The machine incorporates advanced technology, enabling it to operate at high speeds without compromising precision and accuracy. This translates to increased productivity and reduced lead times.b. Versatility: The roll forming machine accommodates a wide range of materials, including steel, aluminum, and alloys. This versatility allows manufacturers from various industries to produce different products without the need for expensive retooling.c. Customization: With the ability to handle complex designs and patterns, the roll forming machine offers manufacturers the flexibility to tailor their products to meet specific customer requirements. This personalized approach enhances customer satisfaction and ultimately leads to increased business opportunities.d. Enhanced Quality Control: The machine's advanced sensors and monitoring systems ensure consistent quality throughout the production process. Real-time data analysis and measurement capabilities enable manufacturers to identify and rectify any defects or inconsistencies promptly.3. Company Introduction:{} is an established leader in the engineering and manufacturing sector, specializing in providing technologically advanced solutions to the global market. With a rich history spanning several decades, the company has gained a solid reputation for its commitment to excellence, innovation, and customer satisfaction.Driven by the desire to push the boundaries of manufacturing capabilities, {} has invested extensively in research and development, resulting in the creation of groundbreaking solutions that optimize production processes and increase overall efficiency.4. Advantages of the Track Roll Forming Machine:The launch of the track roll forming machine by {} is a significant breakthrough in the roll forming industry. The machine's advanced features offer a plethora of advantages that make it a game-changer in manufacturing:a. Increased Efficiency: The high-speed operation and automated features of the machine allow manufacturers to produce more products in less time, significantly improving overall efficiency.b. Cost Reduction: The automation and precision of the roll forming machine minimize material waste, reduce labor costs, and eliminate the need for additional processing steps, resulting in substantial cost savings.c. Improved Product Quality: The machine's integrated quality control systems and real-time monitoring ensure consistent product quality, reducing rejects and warranty claims. This, in turn, boosts customer satisfaction and enhances the company's reputation.d. Sustainable Manufacturing: The track roll forming machine's energy-efficient design and reduced material wastage contribute to sustainable manufacturing practices, aligning with global efforts towards a greener future.5. Future Implications and Conclusion:The introduction of the advanced track roll forming machine by {} showcases the company's commitment to driving innovation in the manufacturing sector. This state-of-the-art machinery is set to transform the production landscape, enabling manufacturers to streamline operations, increase productivity, and improve product quality.The roll forming industry can expect substantial improvements in efficiency, flexibility, and profitability, thanks to this groundbreaking solution. As technology continues to evolve, it is enterprises such as {} that drive progress, revolutionizing traditional manufacturing processes and shaping the future of industrial production.By combining cutting-edge technology with their commitment to excellence, {} is heralding a new era of manufacturing possibilities, revolutionizing the industry and empowering manufacturers to thrive in an increasingly competitive market.

Efficient and Durable C Purlin Steel Machine: A Game-Changer in Steel Construction

C Purlin Steel Machine Revolutionizes the Purlin Manufacturing IndustryThe manufacturing industry has always been known for its never-ending quest to find ways to increase productivity and efficiency while at the same time, decreasing costs. With the advent of technological advancements, companies have started investing in equipment and machinery that can meet their goals and achieve greater success. One such machine that has revolutionized the purlin manufacturing industry is the C Purlin Steel Machine.This machine, which is manufactured by several companies worldwide, including renowned companies such as Kingreal and Xiamen BMS Group, is designed to produce high-quality C-shaped steel channels that are used mainly as support structures in buildings. The machine, which is automated and is controlled by a computer, can produce up to 30 meters of purlins per minute with an accuracy of ±0.5mm.The C Purlin Steel Machine is regarded as one of the most versatile machines used in the production of purlins. It has a hydraulically-powered punching unit that performs profile punching with utmost precision and a pre-cutting unit that eliminates the need for secondary operations such as sawing and drilling. The machine also has a shearing unit that produces clean cuts, and a straightening unit that ensures the finished products are straight, eliminating any possible deformation.Unlike traditional methods of purlin manufacturing that involve several manual operations, the C Purlin Steel Machine is fully automated and can produce purlins of different sizes and thicknesses with minimal or no human intervention. The machine is highly adaptable to a range of materials, including galvanized steel, hot-rolled steel, and other metals, making it perfect for use in various industries.The machine's computer control system is one of its most significant features as it allows for easy and precise adjustments at any given time. Operators can easily program the machine to produce different sizes and designs of purlins, and the system will automatically change dies and cutters, saving time and improving efficiency. Some machines have a touch-screen interface that simplifies the programming process and allows for real-time monitoring of the production process.One company that has benefited significantly from the C Purlin Steel Machine is Kingreal Machinery. The company is a renowned manufacturer of roll forming machines and has been in the business for over 20 years. Kingreal's C Purlin Steel Machine has gained popularity in China and the rest of the world, mainly because of its exceptional quality and performance.According to Mr. Li, the production manager at Kingreal Machinery, the demand for purlins has been on the rise, and the traditional methods of purlin manufacturing could no longer meet market demands. He explains that using the C Purlin Steel Machine has enabled Kingreal Machinery to produce high-quality purlins at a relatively faster pace, allowing the company to keep up with market demand and stay ahead of its competitors.Mr. Li also recognizes the machine's ability to provide better safety standards for their employees, eliminating the risk of accidents in production as the machine does almost all the work, reducing human intervention. Additionally, the machine's efficiency has translated into significant cost savings for the company, eliminating expenses associated with labor and material wastage.The story is not just limited to China as companies worldwide have invested in the C Purlin Steel Machine. One such company is Xiamen BMS Group, which is based in Fujian Province. The company, which specializes in prefabricated living spaces, has invested in the machine to increase production and efficiency. Its previous methods of purlin manufacturing were time-consuming and involved several manual operations, and this was not sustainable in their pursuit of excellent performance and better customer service.The C Purlin Steel Machine has enabled Xiamen BMS Group to produce a wide range of purlins that measure up to 300mm wide and 100mm high, allowing the company to meet various customer needs. The machine's design and automation enable Xiamen BMS Group to produce purlins in large amounts with minimal labor, and the machine's speed has allowed the company to keep up with its growing demand.In conclusion, the C Purlin Steel Machine has revolutionized the purlin manufacturing industry, allowing companies to produce high-quality purlins with precision, at a faster pace, and at reduced costs. The machine's versatile design and automation capabilities enable manufacturers to meet various market demands while providing better safety standards for employees. As technological advancements continue to emerge, we can expect the manufacturing industry to develop even more innovative machines that transform how we do business.

Revolutionary T-Bar Roll Forming Machine Takes Ceiling Grid Systems to New Heights

Title: Revolutionary Ceiling T-Grid T Bar Roll Forming Machine Set to Transform the Construction IndustryIntroduction:In a groundbreaking move, a leading manufacturing company has unveiled its latest innovation, the Fut Ceiling T-Grid T Bar Roll Forming Machine. This state-of-the-art equipment promises to revolutionize the construction industry, enhancing efficiency, precision, and durability in the installation of ceiling grids. With its advanced features and cutting-edge technology, it is set to become an indispensable tool for architects, contractors, and builders worldwide.First and foremost, this innovative machine eliminates the need for manual labor-intensive processes, significantly reducing production time and costs. By streamlining the production process, builders can achieve higher efficiency, meeting project deadlines while minimizing expenses. The machine's automated mechanism ensures precise measurements and consistent quality across the entire grid system, avoiding discrepancies that commonly occur with manual construction methods.One of the standout features of the Fut Ceiling T-Grid T Bar Roll Forming Machine is its versatility. The machine effortlessly adapts to various grid sizes, accommodating different project requirements. This flexibility enables builders to create customized ceiling grids, suiTable for diverse architectural designs and room dimensions. Additionally, the machine can produce T-bars of different materials, including steel and aluminum, making it a handy tool for both residential and commercial construction projects.Another key advantage of this cutting-edge machine is its durability. The use of high-quality materials guarantees longevity, enabling builders to rely on the machine for multiple projects. The steel frame construction ensures stability and robustness, even in demanding work environments. Moreover, the machine's precise engineering minimizes wear and tear, maintaining its efficiency over extended periods of use.The Fut Ceiling T-Grid T Bar Roll Forming Machine is equipped with advanced safety features, prioritizing the well-being of its operators. The inclusion of emergency stop buttons and safety sensors ensures a secure working environment, preventing accidents and injuries. Additionally, the machine's ergonomic design promotes user comfort, reducing strain and fatigue during prolonged use.With environmental sustainability at the forefront, the Fut Ceiling T-Grid T Bar Roll Forming Machine aligns with the industry's growing focus on eco-conscious practices. By minimizing material waste and optimizing production processes, builders can contribute to a greener future. The machine's efficient production capabilities reduce energy consumption, making it an environmentally friendly choice for construction companies.To further enhance customer support, the manufacturing company provides comprehensive training and maintenance services. Skilled technicians offer guidance on the machine's operation and maintenance, ensuring its optimal performance throughout its lifespan. Additionally, the company offers prompt technical support, providing builders with the necessary assistance for any troubleshooting needs.In conclusion, the introduction of the Fut Ceiling T-Grid T Bar Roll Forming Machine is set to revolutionize the construction industry. Its efficiency, precision, and versatility make it an indispensable tool for architects, contractors, and builders. With its cutting-edge technology, durability, and advanced safety features, this machine ensures a seamless and sustainable installation of ceiling grids. Embracing this innovative technology will undoubtedly lead to increased productivity, reduced costs, and overall superior construction quality.

Discover the Latest Innovations in Roll Forming Machine Technology

Title: Advanced Roll Forming Machine Revolutionizes Metal Profiling IndustryIntroduction:The global roll forming machine market is witnessing a significant transformation with the emergence of cutting-edge technologies. One such development is the revolutionary C Roll Forming Machine, which has recently transformed the metal profiling industry. Developed and manufactured by a leading international machinery company (brand name removed), this advanced roll forming machine combines efficiency, precision, and versatility like never before. This news article aims to provide a comprehensive overview of the recent advancements in roll forming technology and shed light on the unique features and benefits of the C Roll Forming Machine.1. The Evolution of Roll Forming Technology:Roll forming technology has come a long way since its inception, and the C Roll Forming Machine represents a major milestone in this journey. Traditionally, roll forming machines were simple and limited in terms of design capabilities. However, with continuous advancements in computer-numerical control (CNC), the industry has witnessed the development of high-performance machines capable of creating complex profiles with utmost precision.2. Unveiling the C Roll Forming Machine:The C Roll Forming Machine introduced by the aforementioned machinery company surpasses traditional roll forming machines with its state-of-the-art technology and unparalleled performance. This advanced machine incorporates a range of cutting-edge features that set it apart from its predecessors and competitors.a. Precise and Efficient Profile Formation:The C Roll Forming Machine utilizes advanced CNC technology to engineer metal profiles with exceptional accuracy and consistency. Equipped with a sophisticated control system, it ensures precise profile dimensions, smooth surface finishes, and fast production cycles. This level of precision facilitates reduced material waste and increased efficiency, making it an indispensable tool for manufacturers in various industries.b. Versatile and Customizable:Flexibility is a key attribute of the C Roll Forming Machine, offering extensive versatility in profile design and customization. Manufacturers can effortlessly create complex shapes, curves, and angles to meet their unique requirements. This level of adaptability allows companies across diverse sectors, such as automotive, construction, and architecture, to explore endless possibilities in their product designs.c. Seamless Integration and Automation:The C Roll Forming Machine embraces automation, enhancing the efficiency of production lines. It seamlessly integrates with existing manufacturing systems, streamlining the entire production process. The machine's user-friendly interface empowers operators to easily program desired parameters, reducing setup time and minimizing errors. Additionally, automatic feeding, forming, and cutting mechanisms enable continuous production and minimize downtime.d. Enhanced Safety and Operator-Friendly Design:Prioritizing safety, the C Roll Forming Machine incorporates various safety features to protect operators during the manufacturing process. Safety guards, emergency stop buttons, and interlocking systems ensure a secure working environment. Furthermore, ergonomic design elements, such as adjustable height and user-friendly controls, minimize operator fatigue and optimize productivity.3. Global Adoption and Industry Impact:The introduction of the C Roll Forming Machine has sparked a global interest in the metal profiling industry. Manufacturers worldwide are recognizing its immense potential to revolutionize their production processes. With its transformative capabilities, this machine not only enhances operational efficiency but also raises product quality standards across industries. Moreover, its ability to minimize material waste aligns with sustainable manufacturing practices, further promoting environmental responsibility.Conclusion:The C Roll Forming Machine has unquestionably propelled metal profiling technology into a new era. Its advanced features, precision, versatility, and safety measures have significantly influenced manufacturing practices across diverse industries. As this technology continues to evolve, it promises to revolutionize the roll forming industry, enabling companies to achieve new heights of productivity, efficiency, and innovation.

Latest Steel Profile Forming Technology Revolutionizes Manufacturing Industry

Steel Profile Forming Machine Enhances Efficiency in Manufacturing IndustryIn recent years, the manufacturing industry has undergone a significant transformation due to technological advancements and automation. One such innovation that is revolutionizing the steel manufacturing process is the Steel Profile Forming Machine. This state-of-the-art machinery combines advanced technology and precision engineering to streamline the production of steel profiles, leading to increased efficiency and productivity in the industry.Steel profiles are essential components in various construction projects, including commercial buildings, bridges, and infrastructural developments. Traditionally, the manufacturing process of steel profiles was time-consuming and labor-intensive. However, with the advent of the Steel Profile Forming Machine, these challenges are being addressed and overcome.The Steel Profile Forming Machine is a sophisticated piece of equipment that automates the bending and shaping of steel profiles. This versatile machinery can handle a wide range of steel profiles, including I-beams, angles, channels, and hollow sections. By utilizing advanced computer numerical control (CNC) technology, the machine can precisely manipulate the steel profiles according to the desired specifications.One of the key features of the Steel Profile Forming Machine is its efficiency in material usage. The machine optimizes the cutting and shaping process, minimizing waste and maximizing the utilization of raw materials. This not only reduces material costs but also contributes to a more sustainable manufacturing process, addressing concerns about environmental impact.The automation provided by the Steel Profile Forming Machine also significantly reduces labor requirements. Previously, workers would manually bend and shape steel profiles, a time-consuming and physically demanding task. With the introduction of this machine, the process is now automated, allowing workers to focus on other critical aspects of the production process. This not only enhances productivity but also improves the safety and well-being of workers.In addition to its efficiency, the Steel Profile Forming Machine also offers high precision and accuracy. With the help of CNC technology, the machine can consistently produce steel profiles with exact dimensions, ensuring uniformity and quality in the final product. This level of precision is vital in construction projects where structural integrity is paramount.Furthermore, the Steel Profile Forming Machine is compatible with various software applications, allowing seamless integration into existing manufacturing processes. This compatibility enables manufacturers to easily incorporate the machine into their production line without disrupting current operations. It also provides opportunities for customization and flexibility in the manufacturing process, catering to specific project requirements.As the global demand for steel profiles continues to rise, the Steel Profile Forming Machine is poised to play a crucial role in meeting this demand efficiently. With its advanced technology, efficiency, precision, and compatibility, this machine has the potential to transform the manufacturing industry and drive further innovation in the steel production sector.Company IntroductionWith a long-standing history in the manufacturing industry, {Company name} has established itself as a leader in providing innovative solutions and machinery for various sectors. Committed to technological advancements, {Company name} strives to improve efficiency and productivity in manufacturing processes.One of the company's notable achievements is the development of the Steel Profile Forming Machine. Leveraging its expertise in precision engineering and automation, {Company name} has successfully introduced this advanced machinery to the market, revolutionizing the steel manufacturing industry.{Company name}'s Steel Profile Forming Machine has been widely adopted by steel manufacturers worldwide, receiving positive feedback and recognition for its outstanding performance and reliability. The company's commitment to research and development ensures that the machine stays at the forefront of industry trends and technological advancements.In addition to its machinery offerings, {Company name} provides comprehensive after-sales services and support to its customers. A team of highly skilled technicians and engineers is available to assist with installation, training, and maintenance, ensuring smooth operation and longevity of the machines.With a strong focus on customer satisfaction, {Company name} continuously strives for excellence in its products and services. Through collaborations and partnerships with industry leaders, the company aims to drive innovation and contribute to the growth and success of its customers.In conclusion, the Steel Profile Forming Machine developed by {Company name} is revolutionizing the steel manufacturing industry by enhancing efficiency, precision, and sustainability. This advanced machinery not only streamlines the production process but also improves worker safety and reduces material waste. With its compatibility and flexibility, the machine is poised to shape the future of steel manufacturing and contribute to advancements in the construction industry.

Scaffolding Metal Plank Roll Forming Machine: A Game-Changing Solution for Efficient Construction Work

(Suggested title: "Innovative Scaffolding Metal Plank Roll Forming Machine Revolutionizes Construction Industry")[Opening Paragraph]In a groundbreaking development, machine manufacturing pioneer {Company Name} has unveiled its latest creation - a cutting-edge scaffolding metal plank roll forming machine. This innovative machinery aims to transform and streamline the construction industry by revolutionizing the production of metal planks used in scaffolding systems. By integrating advanced technology and precision engineering, this state-of-the-art machine is poised to significantly enhance construction efficiency while ensuring the utmost safety for workers.[Company Background]{Company Name}, established in [year], has been a trailblazer in the manufacturing industry. Renowned for its commitment to delivering high-quality machinery, the company has consistently spearheaded advancements in the field. With a dedicated research and development team, {Company Name} continues to pioneer cutting-edge solutions for various industries, empowering businesses worldwide.[Scaffolding Metal Plank Roll Forming Machine]The newly introduced scaffolding metal plank roll forming machine utilizes the latest roll forming technology to transform raw materials into seamless metal planks with exceptional precision and speed. By integrating a series of automated processes, this machine eliminates traditional manufacturing constraints, facilitating rapid production without compromising quality.[Benefits and Features]1. Enhanced Efficiency: The scaffolding metal plank roll forming machine can significantly expedite production without incurring additional labor costs. Its streamlined manufacturing process ensures high productivity and allows for large-scale production, meeting the demands of even the most challenging construction projects.2. Customization Options: This cutting-edge machine accommodates diverse specifications, enabling the production of metal planks tailored to the unique requirements of different scaffolding systems. Its flexibility ensures that construction firms can obtain customized solutions, eliminating the need for costly customization or outsourcing.3. Safety First: The scaffolding metal plank roll forming machine incorporates advanced safety features, guaranteeing the well-being of workers. With automated controls and mechanisms, it minimizes the risk of accidents or injuries, fostering a secure working environment.[Industry Impact]The introduction of the scaffolding metal plank roll forming machine is poised to revolutionize the construction industry on multiple fronts. By streamlining the manufacturing process, it not only reduces production time but also augments overall construction efficiency. Consequently, construction companies can now complete projects more rapidly and allocate resources more effectively, driving economic growth and enhancing competitiveness.Moreover, the machine's ability to produce customized metal planks empowers construction firms to cater to a wider range of projects, expanding their market reach. This flexibility allows for greater innovation and adaptability, as scaffolding systems can be tailored precisely to the unique requirements of each construction site.Additionally, the machine's emphasis on safety aligns with the industry's growing focus on worker welfare. By prioritizing safety measures, the construction sector can mitigate hazards and reduce workplace accidents, ensuring a safer working environment for all.[Conclusion]The introduction of the scaffolding metal plank roll forming machine marks a significant milestone in the evolution of the construction industry. Its innovative features and capabilities are set to transform the manufacturing process and elevate overall efficiency, while simultaneously addressing the industry's heightened emphasis on worker safety. As {Company Name} continues to push the boundaries of engineering and manufacturing, it reinforces its position as a global leader in driving positive change across industries.