Parameter

| Rollformer | Product | Combined production speed * | Machinable gauges | Hook type | Compatibility | ||

| D54 | T4 | Cross T and Main Runner | 10 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| D57 | T4 | Cross T | 31 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| D58D | T4 | Cross T | 32 m/min | 0.2 - 0.6 mm | Alloy hook | More | |

| D59D | T4 | Main Runner | 34 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| D51 | T4 | Cross T and Main Runner | 30 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| Automation System | |||||||

| DA5MR | Main runner cardboard box packaging system | D59D | More | ||||

| DA5CT | Cross T cardboard box packaging system | D57, D58D | More | ||||

Product Description

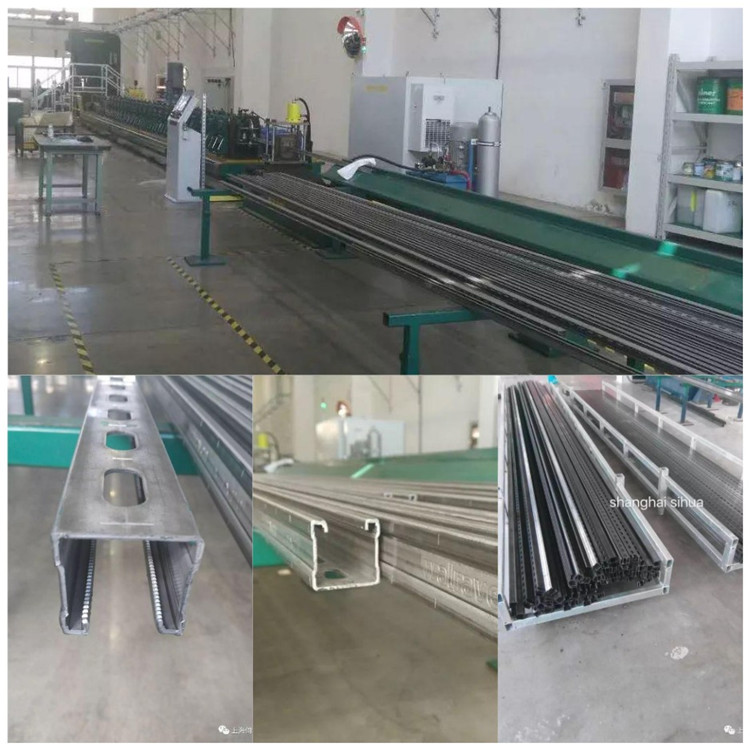

The light steel keel is a building metal skeleton that is rolled by a cooling process by high-quality continuous hot-dip aluminum zinc strip. The shape decoration of the finished non-loaded wall made of paper gypsum boards, decorative gypsum boards. Suitable for modeling decorations of a variety of building roofs, internal and external walls of the building and the base materials of the hooded ceiling. Production process: De-coiler →roll forming profile →cutting table →packing table (hydraulic system given power) all parts were control by electrical control system.

Video