Feature

| No. | Item | Feature |

| 1 | Hydraulic 2 head De-coiler | Double head decoiler can been choice. There are 5 choice. 1. Manual double head decoiler. 2. Hydraulic double head decoiler. 3. Hydraulic expansion Electric Rotary Exchange double head decoiler. 4. Hydraulic expansion double head decoiler with wagon. 5. Hydraulic expansion motor decoilers. |

| 2 | High speed high precision roll forming machine | European design and high precision working table for accurate profile forming and durable machine. High speed high precision shear cutting roll forming machine. 2.1 Working speed: Standard machine working speed is 45-60m per min. Top machine working speed is 80-120M per min. 2.2 Roller material life is more than 5 years, used Japan processing equipment. Roller material: Cr12MoV vacuum heat treatment hardness:58-62HRC. 2.3 The machine base was been elevated temperature to eliminate inner force for prolong machine life. 2.4 The machine working table using large CNC whole processing for high precision flatness. 2.5 Wall frame is been CNC processing, distance is 0.02mm between frame and slider. |

| 3 | Flying shear Cutting table | 3.1 Cutter is Japan material: SKD11 vacuum heat treatment, hardness 58 - 62HRC. 3.2 Wagon transfer method is Guide rail and ball screw shearing system or rack and pinion. 3.3 Shear controller used German brand or Italian brand. 3.4 Servo motor brand Yaskawa /SEW up choice. 3.5 Working table with large CNC whole processing, the working table is high precision. 3.6 Cutting table is welded as box body structure by one type put screw and guardrail inside for safe and durable cutting table installed screw oiling device. 3.7 The left and right ends of the cutting table are provided with a dust cover, a protecting screw and guide rail. 3.8 Cutting table base using Q235B steel gas protection welding, after 2 times the overall tempering, eliminating the internal force generated by welding. Using sand blasting, spray 2 times 2 times anti rust primer, top coat, paint color is gray. |

| 4 | Hydraulic station | Save energy,stable hydraulic output system. International brand spare parts for reduce maintenance cost. 4.1 Hydraulic plunger pump:TAIWAN BRAND. 4.2 Motor power SIEMENS. 4.3 Hydraulic solenoid value number: 3 sets, SIHUA. 4.4 Hydraulic accumulator capacity 25L. 4.5 Tank volume:220L-400L. 4.6 Pressure sensor: German brand. 4.7 Filtration brand is USA brand. |

| 5 | Electricity system | Human interface show all function and easy control product line and easy maintenance. International brand spare parts for reduce maintenance cost. 5.1 Encoder: Japanese brand 5.2 PLC: Japanese bran 5.3 Human interface: German brand /china brand 5.4 Relay and breaker plug brand: Schneider. |

| 6 | TransmissionAnd packing table | Fast output finished products There are 2 choose 1. Transmission and manual packing table. 2. Automatic stacker. |

Product Description

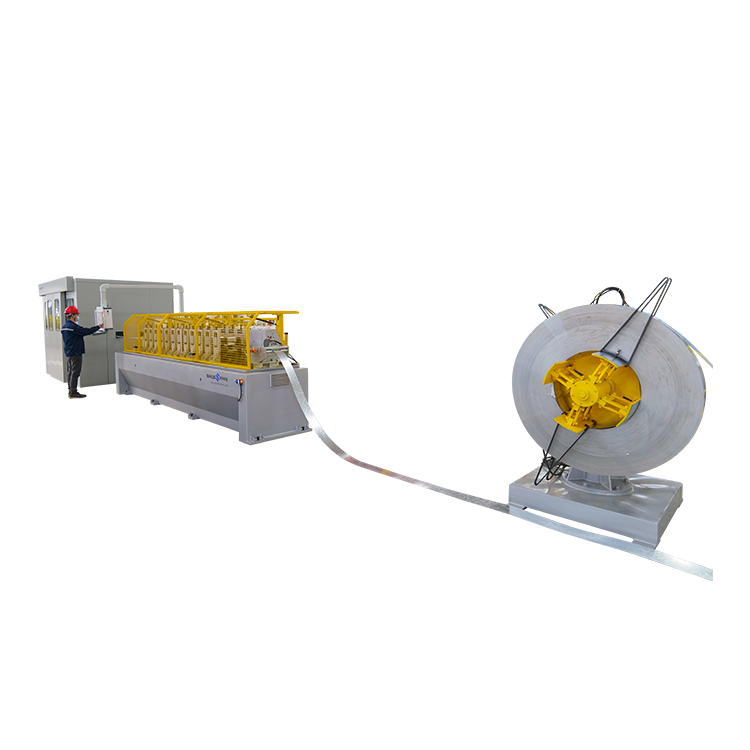

C stud roll forming machine | Cd roll forming machine | C channel roll forming machine. C stud roll forming machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type.Specification

Production process: De-coiler →roll forming profile →cutting table →packing table (hydraulic system given power) all parts were control by electrical control system| NO. | Item | Specification |

| Material | Raw material | Galvanized steel |

| Thickness | 0.3-0.8 mm | |

| Machine | Roller station | 10-14steps |

| Shaft diameter | 50 mm | |

| Solid shaft material | 40CR quenching & tempering & treatment | |

| Roller material hardness 58-62 HRC | Cr12MOV | |

| Machine size | About 18*3.6*1.6 m | |

| Machine weight | About 15TONS | |

| Machine color | As customer need | |

| Working speed | 60-120 m/min | |

| Cutter | Hardness | 50-65 HRC |

| Cutting tolerance | ± 1mm | |

| Material | SKD11 | |

| Operate | Hydraulic cutting | |

| Power | Driving way | Reducer drive system or Gear combi drive system |

| Main motor | 11-20 KW | |

| Pump motor for cutter | 11 KW-20kw | |

| Voltage | 380V/50HZ, 3P or Customized as customer' request | |

| Control system | PLC brand | MITSUBISHI/Siemens |

| HMI Screen | Kinco /Siemens | |

| Language | Chinese and English or add customer need language | |

| Decoiler | Operation | Manual or automatic |

| Weight capacity | 3 Tons*2 pc |

More for You Choose

1. Angle bead roll forming machine Angle bead roll forming machine | Corner bead production line | Metal angle bead machine | Corner bead roll forming machine | V shape roll forming machine | Steel wall angle bar roll forming machine. Angle bead roll forming machine popular sell in many countries, size common include 20*20 mm, 25*25 mm, 27*27 mm, 30*30 mm. Product thickness common between 0.3-0.6 mm, machine details is like up type. 2. Omega profile roll forming machine Omega profile roll forming machine | Omega channel roll forming machine | Omega channel roll forming machine | Top hat roll forming machine. Omega profile roll forming machine popular sell in many countries. Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type. 3. C channel 3 size in 1 roll forming machine 3 in 1 c channel machine | multiple c channel machine | C u channel roll forming machine. Multiple C channel machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type. 4. C stud (CD) roll forming machine C stud roll forming machine | Cd roll forming machine | C channel roll forming machine. C stud roll forming machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type. 5. U stud (UD) roll forming machine U stud roll forming machine | ud roll forming machine | u channel making machine. u stud roll forming machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type. 6. U channel roll forming machine U channel roll forming machine | gypsum u channel making machine | U stud roll forming machine. U channel roll forming machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type. 7. T grid roll forming machine Spring T grid machine |T bar rolling machine | Main T machine | Cross T ceiling keel machine. T grid roll forming machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 8-15 m/min, with servo motor speed can max reach to 10-30 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type.

Video

Company Profile

Shanghai sihua precsion machinery co., ltd. is one professional roll forming machine manufacturer, 18 years working experience and 400 worker provide service for you. Products mainly include: drywall profile roll forming machine, 120M per min stud and track roll forming machine, ceiling t bar roll forming machine, cable tray roll forming machine, c struct roll forming machine, upright rack roll forming machine, rack roll forming machine, scaffold deck roll forming machine and customized machine etc. Our customer We roll forming machine sell to lots of countries in the world, like Italian, France, Belgium, Poland, CANADA, American, Algentina, Egypt, Tusnia, algeria, Thailand, Vietnam philippines, Australia ect.